Introduction:

In the past few years, global supply chain disruptions have become a common topic of conversation, yet many industries still find themselves struggling to navigate these challenges. From the early days of the COVID-19 pandemic to geopolitical tensions and natural disasters, global supply chains have been tested in ways few could have predicted. This article explores the far-reaching consequences of these disruptions, and more importantly, how different industries are adapting to these shifts. With careful analysis, we will examine the long-term implications of global supply chain disruptions and how businesses can turn challenges into opportunities.

1. Understanding the Global Supply Chain Landscape

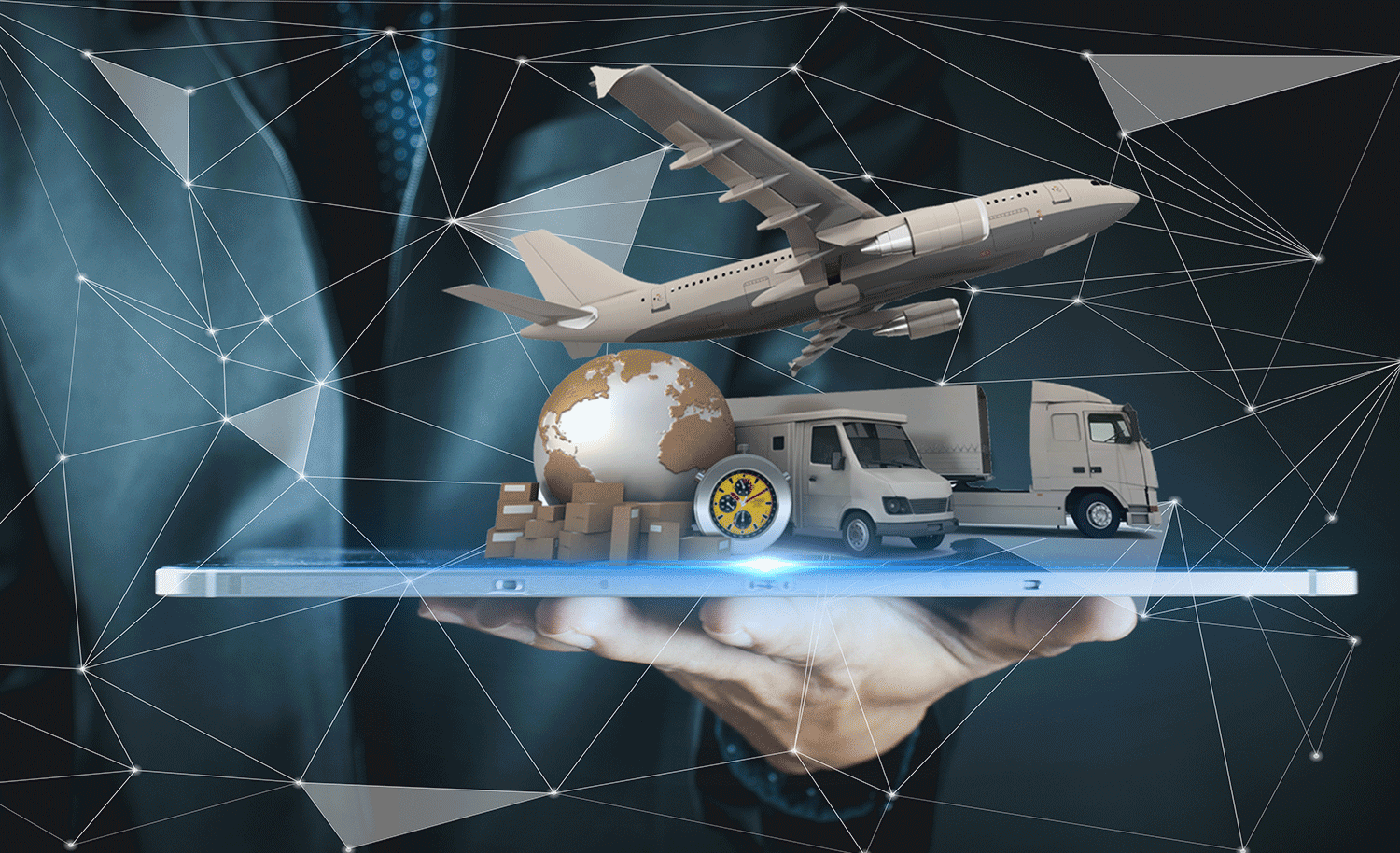

The global supply chain is more than just the delivery of goods from point A to point B. It’s a complex, interconnected system involving manufacturers, suppliers, warehouses, transportation companies, and retailers. The world’s supply chains are deeply integrated, meaning that disruptions in one part of the world can create ripple effects that reverberate across industries.

Historically, global supply chains were optimized for cost reduction and efficiency. Companies sourced materials from the cheapest locations, and inventory was carefully balanced to avoid excess stock or delays. However, recent global events have shown that relying on a just-in-time inventory model and long supply lines is a risky strategy in the face of unforeseen events.

2. The Ripple Effects of Disruptions

Pandemics and Public Health Crises

The COVID-19 pandemic was perhaps the most disruptive event in recent memory, shutting down factories, disrupting transportation networks, and causing widespread labor shortages. Supply chains came to a grinding halt as industries scrambled to secure essential goods. The pandemic also brought to light the vulnerabilities in the globalized system, including the dependency on single-source suppliers and global production hubs.

Geopolitical Tensions and Trade Wars

Increasing geopolitical tensions, especially between major economies like the U.S. and China, have led to trade wars and tariffs that complicate global trade. Industries that rely on free trade and open borders have faced challenges as tariffs increase costs and reduce access to critical components.

Natural Disasters and Environmental Factors

Natural disasters, such as hurricanes, floods, and wildfires, have disrupted production lines and transportation routes, especially in regions that serve as global manufacturing hubs. These environmental disruptions have underscored the need for disaster-resilient supply chains that can respond quickly and minimize the damage.

3. Industry-Specific Impacts

Manufacturing

In the manufacturing industry, the disruptions have been stark. For example, delays in the shipment of components like semiconductors have slowed down car production globally. Supply chain managers are now prioritizing automation and the reshoring of key production stages to avoid the risks associated with long-distance shipping.

Retail

Retailers, particularly in e-commerce, have felt the pinch as supply chain delays led to empty shelves and longer delivery times. Retailers are investing heavily in last-mile delivery innovations and adopting better inventory management systems to manage demand fluctuations more efficiently.

Healthcare

Healthcare industries were among the hardest-hit by supply chain disruptions, as the demand for medical supplies and personal protective equipment (PPE) skyrocketed during the pandemic. Shortages in critical supplies led to life-threatening delays in treatments. Moving forward, healthcare companies are exploring more resilient supply chain models, often relying on localized suppliers and digital tracking technologies.

4. Adaptation Strategies: Navigating the New Normal

Resilience through Diversification

One of the key strategies for businesses today is diversifying supply sources. Companies are looking to reduce their dependency on a single supplier or region and are spreading their risk across multiple countries. For example, automakers are now sourcing microchips from multiple suppliers rather than relying on a single dominant supplier.

Supply Chain Visibility

With the increasing complexity of global supply chains, having visibility into every stage of the process has never been more critical. Modern technologies, such as blockchain, IoT sensors, and AI-powered analytics, allow companies to track goods in real time and predict potential disruptions before they occur.

Nearshoring and Localization

The trend of nearshoring, or relocating production closer to home markets, has gained significant momentum. While offshoring to low-cost countries was once the norm, many businesses are now opting to build supply chains that are more geographically diversified, reducing dependency on distant regions and boosting local economies.

5. The Future of Supply Chains: Predictions and Trends

Automation and Robotics

Automation will play a huge role in shaping the future of supply chains. From autonomous trucks to robots in warehouses, automation promises to streamline operations, reduce human error, and cut down on labor costs.

AI and Machine Learning

Machine learning algorithms will be used to predict demand patterns, optimize inventory management, and identify weak points in supply chains before they lead to disruptions.

Sustainability and Ethical Sourcing

Environmental and social factors will become increasingly important in supply chain decision-making. Companies will be held to higher standards regarding ethical sourcing, labor practices, and environmental impact.

Conclusion: Turning Disruptions into Competitive Advantage

Global supply chain disruptions, while challenging, also present significant opportunities for innovation and transformation. Businesses that embrace flexibility, technological advancements, and sustainability will be better equipped to handle future disruptions. By rethinking traditional supply chain models, companies can transform adversity into a competitive advantage in an increasingly volatile world.