Introduction

The world of industrial manufacturing and production has always been synonymous with constant evolution. From the early days of the industrial revolution to today’s sophisticated, automated factories, industry has embraced technological advances to improve efficiency, reduce errors, and lower costs. Among the most promising technological innovations of the past decade is Augmented Reality (AR). Originally popularized in the gaming world, AR has begun making its way into the industrial sector, promising to significantly enhance productivity, safety, and training processes.

This article explores the ways in which AR is transforming industries, from manufacturing to maintenance, and how its integration can result in greater productivity and reduced operational risks. Let’s take a look at the potential of AR in industrial settings.

1. What is Augmented Reality?

Before diving into the specifics of industrial applications, it’s essential to understand what AR is. At its core, augmented reality refers to the technology that overlays digital information—like images, videos, or sounds—onto the real world. Unlike virtual reality (VR), which immerses users in a fully synthetic environment, AR enhances the physical world by adding virtual elements to it in real-time.

This technology can be experienced through a variety of devices, from smartphones and tablets to specialized AR glasses and headsets. AR’s potential in industrial applications is vast, ranging from design and maintenance to real-time data visualization and training simulations.

2. Enhancing Industrial Design and Prototyping

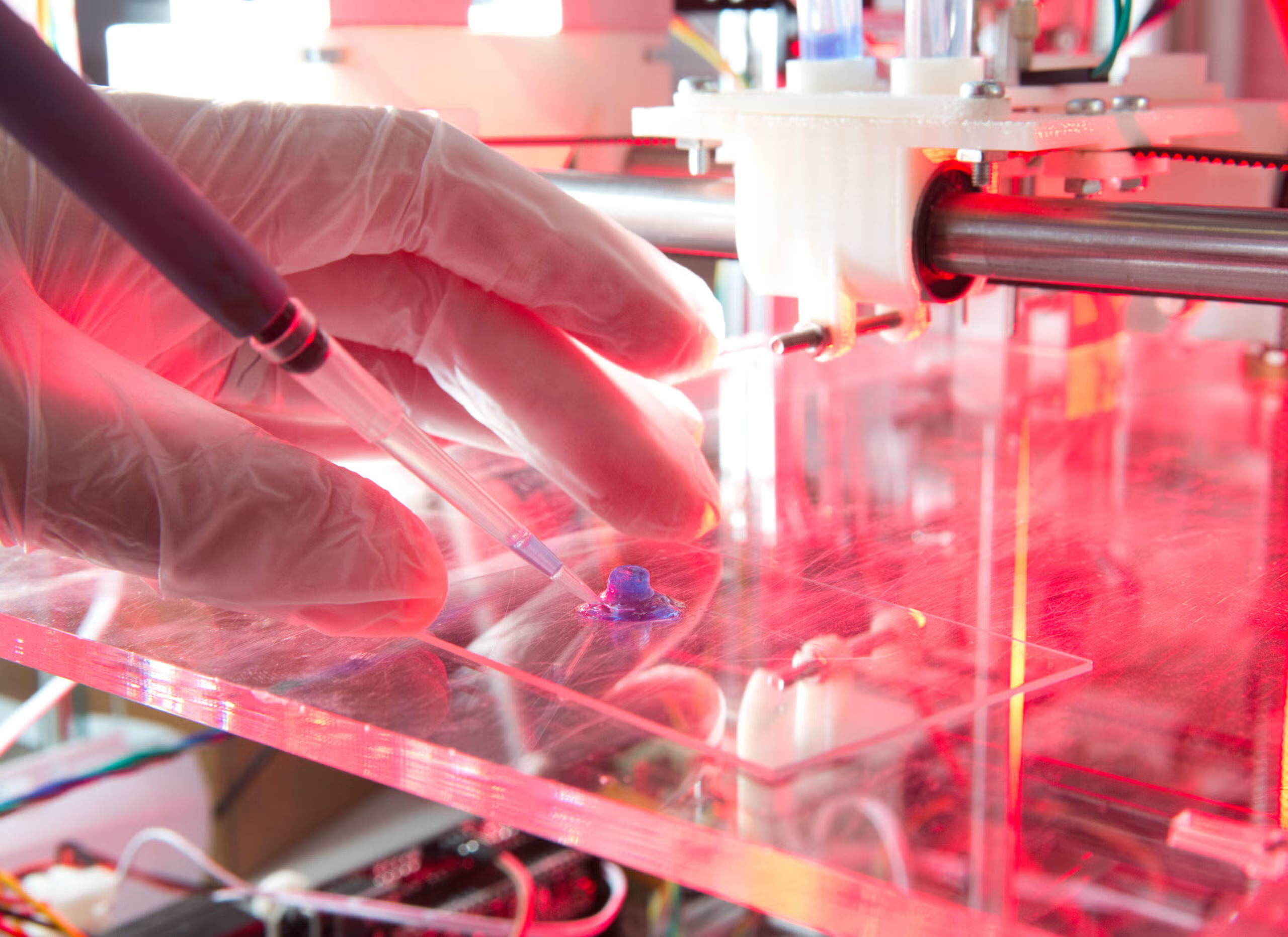

One of the early applications of AR in the industrial sector is in the design and prototyping phase. Traditionally, designing and prototyping new machinery or equipment has been an expensive and time-consuming process. It involves creating physical prototypes, conducting tests, and iterating based on feedback.

With AR, designers can overlay virtual 3D models onto real-world environments. Engineers can examine how the components of a machine will fit together in the real world, even before manufacturing begins. This real-time visualization allows for rapid iteration, faster feedback, and the ability to spot design flaws before committing to physical prototypes.

For example, a team working on a new assembly line robot can use AR to visualize how it will interact with existing machinery and workflow. This helps in minimizing the risk of incompatibilities and ensures smoother integration into the factory environment.

3. Revolutionizing Manufacturing Processes

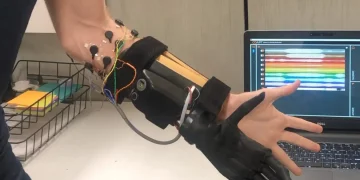

In a manufacturing environment, AR can enhance the production process by offering real-time guidance and information to workers. Traditional methods of manufacturing often involve lengthy training and reliance on printed manuals, both of which can lead to errors and inefficiencies.

With AR, workers can access detailed instructions, schematics, and step-by-step guidance directly in their line of sight, often through AR glasses or smart helmets. This means that workers no longer need to refer to paper-based manuals or leave their workstation to consult supervisors. The technology helps eliminate errors and reduces the time spent on training, leading to higher productivity.

For instance, in complex assembly tasks, workers can see digital overlays of the assembly instructions, complete with animations that show them exactly where each part fits. This helps them assemble products faster, with fewer mistakes, improving both quality and speed.

4. Predictive Maintenance and Real-Time Problem Solving

One of the most powerful applications of AR in industrial environments is in predictive maintenance. Maintenance is a critical aspect of ensuring the longevity and efficiency of industrial equipment, but traditional methods can be costly and reactive. Instead of waiting for equipment to fail and then repairing it, predictive maintenance powered by AR allows companies to anticipate problems before they occur.

Through AR-enabled devices, workers can access real-time data on the condition of machinery. By overlaying this data onto the physical equipment, technicians can quickly identify issues, such as unusual vibrations, temperature changes, or wear and tear. In some cases, AR can even guide them through troubleshooting and repair procedures, reducing downtime and increasing the overall productivity of the operation.

Additionally, AR can facilitate remote troubleshooting. Experts or engineers can provide real-time assistance to technicians on-site by guiding them through maintenance procedures via live video feed or by overlaying instructions onto the technician’s view of the equipment. This reduces the need for expensive travel or extended downtime while ensuring that repairs are done efficiently.

5. AR in Worker Training and Skill Development

Training workers in complex industrial environments often requires hands-on experience, which can be both time-consuming and risky. By incorporating AR, workers can undergo immersive training experiences without the need to interact with expensive or potentially dangerous equipment.

For example, AR can simulate real-world scenarios that workers may encounter on the job, allowing them to practice troubleshooting, repairs, and emergency response procedures in a safe environment. This type of training reduces the risk of accidents and injuries while ensuring that workers gain practical experience.

Furthermore, AR enables remote training, where an expert can guide workers through training procedures from a different location. By simply using AR devices, workers can receive step-by-step instructions, visual aids, and interactive tutorials that enhance their learning experience. This is particularly useful for companies with multiple sites or for training new employees across the globe.

6. Improving Safety Standards and Reducing Errors

In industrial environments, safety is always a top priority. Traditional methods of ensuring safety often involve manual inspections, lengthy safety briefings, and the use of physical safety equipment. While these methods are effective, they can also be time-consuming and prone to human error.

AR can enhance safety protocols by providing workers with real-time safety information and warnings. For example, AR glasses can alert workers to hazardous conditions, such as high temperatures or the presence of toxic substances, as they approach dangerous areas. This immediate feedback can help prevent accidents and ensure that safety protocols are always followed.

Moreover, AR can assist in reducing human error. By displaying real-time data, work instructions, and safety reminders, AR ensures that workers don’t overlook important details. This level of precision is especially critical in high-risk industries like aerospace or nuclear power, where even a small mistake can have serious consequences.

7. AR and Supply Chain Management

Supply chain efficiency is another area where AR can make a significant impact. In many industrial sectors, managing inventory and logistics can be a cumbersome process involving paper-based tracking and manual data entry.

By integrating AR with inventory management systems, companies can automate and streamline the process. Workers can simply use AR devices to view inventory information, track shipments, and even check the status of deliveries in real-time. This eliminates the need for manual record-keeping, reduces the likelihood of errors, and ensures that the right materials are always available when needed.

In addition, AR can provide warehouse workers with real-time route guidance to locate items quickly, reducing the time spent searching for materials and improving overall efficiency.

8. The Future of AR in Industry

As AR technology continues to evolve, its applications in the industrial sector will become even more sophisticated. The advent of 5G networks and improved connectivity will allow for real-time data sharing and collaboration on a global scale. This means that companies can implement AR-driven solutions across multiple locations, ensuring consistent processes and standardization.

Moreover, advancements in machine learning and AI will enable AR systems to adapt and learn from the data they collect. For example, an AR system could monitor a machine’s performance over time and predict when it is likely to need maintenance, providing even more proactive support.

With ongoing developments in AR technology, the possibilities for improving industrial productivity are virtually limitless. From smart factories to advanced robotics, AR will play a key role in shaping the future of industry.

9. Challenges and Considerations

While the potential for AR to revolutionize industrial productivity is clear, there are still challenges that need to be addressed. One of the biggest hurdles is the cost of implementation. AR hardware, such as smart glasses or headsets, can be expensive, especially for smaller companies. However, as the technology matures, prices are expected to drop, making it more accessible to a wider range of businesses.

Another challenge is the integration with existing systems. Many industrial environments rely on legacy systems, which may not be compatible with newer AR technologies. Ensuring seamless integration with these systems will require significant investment in software and training.

Finally, as with any new technology, there will be a learning curve. Workers will need to be trained to use AR devices effectively, and businesses will need to ensure that their workforce is ready for this transition.

Conclusion

In conclusion, Augmented Reality has immense potential to improve industrial productivity across a wide range of sectors. From enhancing design and prototyping to streamlining manufacturing processes, improving safety, and enabling predictive maintenance, AR offers a wealth of opportunities to drive efficiency and reduce costs.

While there are challenges to overcome, the long-term benefits of AR integration in industrial environments are clear. As the technology continues to evolve, we can expect to see even more transformative applications, reshaping the future of manufacturing and industrial operations.