Introduction

In today’s rapidly evolving world, labor shortages in various industries are becoming a pressing concern. As businesses grapple with an aging workforce, reduced workforces due to global events, and changing societal values towards work, the demand for labor often outstrips supply. This has led many to turn to innovative solutions like robotics to bridge the gap. With advancements in artificial intelligence (AI), machine learning, and automation, robotics technology has reached a level where it is becoming an indispensable tool for industries across the globe.

But can robotics truly be the solution to the ongoing labor shortages? Or is this just another technological promise with limited real-world impact? Let’s delve into the relationship between labor shortages and robotics, exploring how they intersect, the benefits, and the challenges involved in implementing these systems.

1. The Rise of Labor Shortages: Causes and Consequences

1.1 The Global Labor Crunch

Over the past decade, industries worldwide have faced increasing difficulties in finding and retaining workers. Factors contributing to this labor crunch include:

- Aging Populations: In many developed nations, the population is aging rapidly. With fewer young people entering the workforce, there is a growing gap in labor supply, particularly in sectors like manufacturing, healthcare, and agriculture.

- Pandemic Effects: The COVID-19 pandemic severely disrupted the global labor market, leading to mass layoffs, early retirements, and widespread hesitancy to return to certain jobs. The “Great Resignation” that followed has had a long-lasting impact on sectors like hospitality, retail, and transportation.

- Skill Gaps: As industries evolve, so too does the demand for specialized skills. Many workers are either underqualified or unwilling to meet these higher requirements, leading to a mismatch between available workers and the jobs that need filling.

- Changing Attitudes Toward Work: A shift in work culture, especially among younger generations, has led to a preference for remote work or flexible working hours. Many workers are also seeking roles that align with their personal values, such as those that prioritize sustainability and social impact.

1.2 Impacts on Industry

Labor shortages don’t just affect the quantity of the workforce—they also have significant economic and operational consequences. Businesses face:

- Increased Labor Costs: With fewer workers available, wages rise to attract talent, putting pressure on companies to pay higher salaries. This can erode profitability and reduce operational efficiency.

- Reduced Productivity: Without enough workers, production processes slow down, resulting in a decrease in output. This not only affects revenue but can also harm a company’s ability to meet customer demand.

- Strained Supply Chains: With limited human resources, industries such as logistics and transportation are experiencing delays, shortages, and inefficiencies, which reverberate throughout the entire supply chain.

2. Robotics: A Powerful Solution?

2.1 Automation and Robotics in Industry

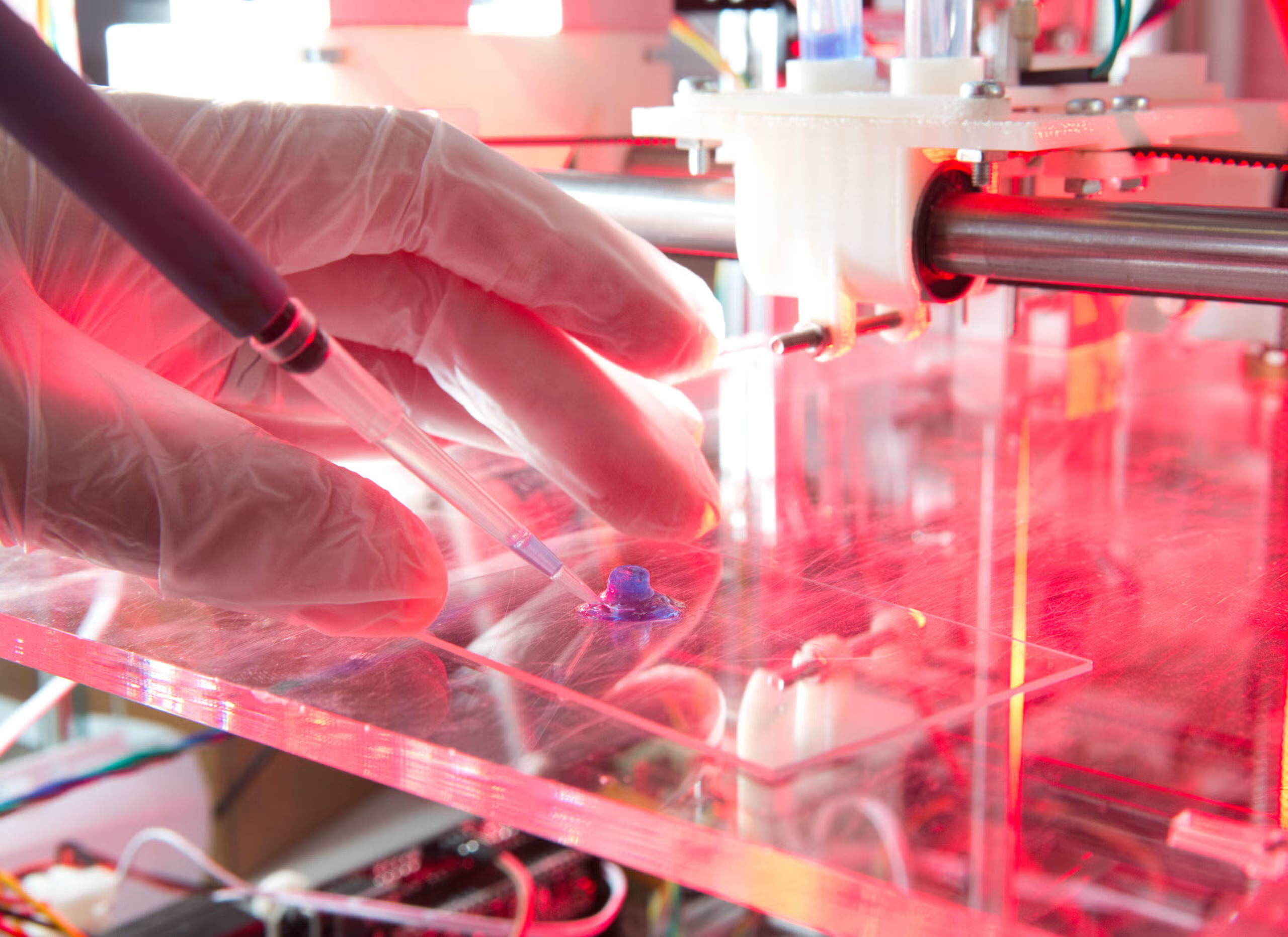

The introduction of robotics and automation has already revolutionized several industries, including automotive, electronics, and consumer goods manufacturing. Robots are not just limited to performing repetitive tasks—they are capable of highly specialized and complex functions, thanks to advancements in AI, machine learning, and vision systems.

For example, robots in manufacturing plants can assemble products, package goods, and even perform quality checks. In the agricultural sector, drones and autonomous vehicles are used for crop monitoring and harvesting. Robotics has the potential to step in where human labor is scarce or unavailable, helping to maintain production rates and meet consumer demand.

2.2 Key Benefits of Robotics in Overcoming Labor Shortages

- Increased Efficiency and Productivity: Robots can work around the clock without the need for breaks or downtime, making them ideal for high-demand industries. Their precision and reliability lead to faster production times and fewer errors, improving overall efficiency.

- Filling Low-Wage or Undesirable Jobs: Many industries suffering from labor shortages, such as agriculture, hospitality, and logistics, often have high turnover rates and jobs that are physically demanding or poorly paid. Robotics can take on these roles, allowing humans to focus on higher-value tasks.

- Enhanced Safety: Dangerous tasks, such as working with hazardous materials, lifting heavy objects, or operating in extreme environments, can be delegated to robots, reducing workplace injuries and improving overall safety for human workers.

- Cost Reduction Over Time: While the initial investment in robotics can be high, the long-term savings from improved efficiency, reduced labor costs, and fewer errors can make robotics a cost-effective solution for companies.

- Addressing Skill Gaps: Robots, once programmed, can perform tasks that require skills that are difficult to find in the labor market, such as advanced precision tasks in manufacturing. This helps companies fill positions that would otherwise remain vacant.

2.3 Types of Robotics That Are Making a Difference

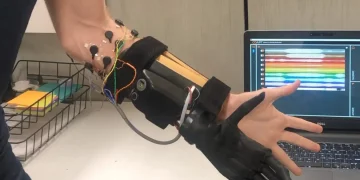

- Collaborative Robots (Cobots): Cobots are designed to work alongside human workers, performing repetitive or physically demanding tasks. This makes them ideal for industries where humans are still needed for supervision or decision-making, but robotics can handle the bulk of the repetitive work.

- Autonomous Mobile Robots (AMRs): These robots are used in logistics and warehousing, moving goods from one location to another without human intervention. AMRs are vital in supply chain management, reducing the reliance on manual labor in warehouses and distribution centers.

- Service Robots: In hospitality and healthcare, service robots are increasingly used to deliver goods, assist with patient care, or clean and sanitize areas. This is especially useful in sectors struggling with labor shortages.

- Agricultural Robots: Autonomous tractors, harvesters, and drones are transforming agriculture by increasing efficiency, reducing costs, and allowing for precision farming practices that were once unimaginable.

3. Challenges to Widespread Adoption of Robotics

While the potential benefits of robotics in addressing labor shortages are clear, there are several hurdles to overcome before they can be universally implemented.

3.1 High Initial Costs

The upfront investment in robotics technology, including the purchase, installation, and maintenance of robots, can be prohibitively expensive for small and medium-sized enterprises (SMEs). While robots can eventually lead to cost savings, the initial financial barrier remains a significant challenge.

3.2 Job Displacement and Ethical Concerns

As robots take over certain tasks, concerns about job displacement arise. Entire sectors that rely heavily on human labor may see significant reductions in their workforce. This leads to questions about the ethical implications of replacing workers with machines, particularly in areas where alternative employment opportunities may not exist.

3.3 Technological and Operational Challenges

Implementing robotics requires significant technical expertise, and businesses may struggle to integrate new robots into existing systems. Additionally, robotics technologies require regular maintenance and calibration, and in industries with unpredictable environments, robots may not be as adaptable as humans.

3.4 Public Perception and Resistance

There is often resistance to automation, particularly from labor unions and workers who fear job loss. Public perception also plays a key role in the acceptance of robotics in the workplace. Governments and companies need to create policies and strategies to manage the transition from human labor to automation, focusing on reskilling workers and managing social impacts.

4. The Future of Robotics and Labor Shortages

As technology continues to advance, robots will become even more capable of taking on a wider range of tasks. In the future, we might see:

- Robots with Advanced AI: AI will enable robots to make more complex decisions, allowing them to adapt to varying conditions and handle more dynamic environments, such as managing supply chains during disruptions or reacting to changes in production requirements.

- More Collaborative Work: Human workers and robots will continue to work side by side, with robots taking on more physical tasks while humans focus on creativity, strategic decision-making, and interpersonal roles.

- Expansion into New Industries: As the technology matures and becomes more affordable, robotics will expand into industries previously not thought to be suitable for automation, including healthcare, retail, and even education.

- A New Workforce Ecosystem: The widespread use of robotics will lead to a redefinition of what the workforce looks like. The demand for workers in traditional roles may decrease, but there will be a growing need for skilled professionals who can design, program, and maintain robots.

5. Conclusion: Robotics as a Solution to Labor Shortages

Robotics holds tremendous potential for mitigating the effects of labor shortages in many industries. From improving productivity and efficiency to filling gaps in jobs that are too physically demanding or unappealing, robots can provide the support needed to ensure that businesses continue to thrive despite the challenges posed by labor scarcity.

However, while robotics can be a key solution, it is not a panacea. The integration of robots into the workforce must be managed carefully to avoid job displacement, ensure ethical practices, and make the technology accessible to all types of businesses. As we move forward, robotics will play an increasingly vital role in reshaping industries, helping companies not only survive but thrive in a world of labor shortages.