Imagine waking up in a house that was designed and built specifically for you, with every corner customized to fit your unique style. A home that didn’t require months of construction or thousands of labor hours to bring to life. What if the house you live in could be 3D printed?

As futuristic as it may sound, 3D printing has already started revolutionizing industries like medicine, aerospace, and fashion. Now, it’s making its way into the world of construction, and the potential implications for how we design and build our homes are extraordinary.

But how feasible is it? What are the benefits, challenges, and potential of 3D printed homes? Let’s explore these questions in detail.

A Revolution in Construction

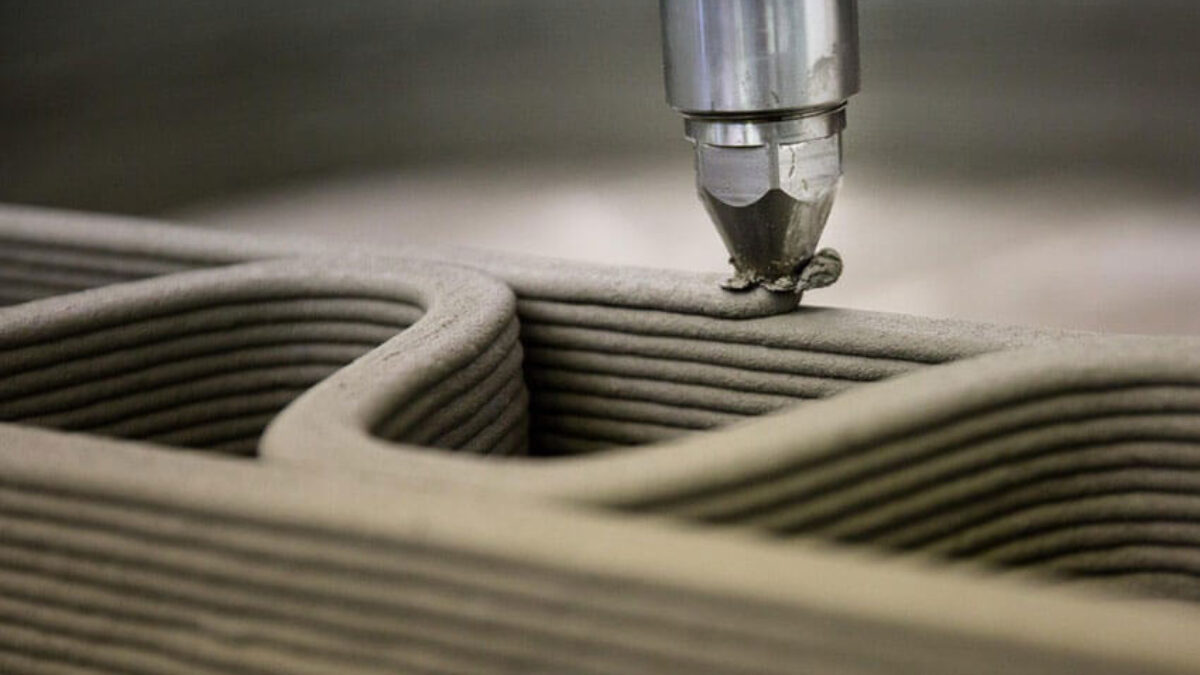

3D printing, or additive manufacturing, is a process where objects are created by laying down layers of material, one after the other, based on a digital design. In the context of housing, it involves the use of specialized printers to create structures using concrete, plastic, or other composite materials. This technology has been in development for over two decades, but it is only in recent years that it has gained serious attention for use in residential construction.

The Technology Behind 3D Printed Homes

The fundamental technology behind 3D printing homes is a combination of robotics, computer-aided design (CAD), and materials science. Large-scale 3D printers, some of which are the size of a small building, are programmed with blueprints that guide the printer’s movements. These printers extrude a paste-like mixture of concrete or a synthetic polymer, layer by layer, to create walls, floors, and even roofing structures.

In some cases, 3D printing technology can also be combined with pre-built components, such as windows, doors, and insulation, creating a hybrid construction method. The design process itself is highly flexible and customizable, allowing for unique and intricate home layouts that would be difficult or expensive to achieve with traditional construction techniques.

Advantages of 3D Printed Homes

While the concept may still seem like science fiction to some, the advantages of 3D printing for home construction are clear and numerous. Let’s break them down:

1. Cost Efficiency

Traditional construction methods involve a lot of material waste and labor costs. 3D printing, on the other hand, allows for precise material usage, reducing both. According to various reports, 3D printed homes can be built at a fraction of the cost of traditional homes. The reduction in labor costs is particularly striking, as a significant portion of traditional construction costs is tied to the workforce.

For example, a company in Mexico, ICON, successfully built homes using 3D printing technology for just $4,000—a fraction of the price of typical housing in the area. This affordability could make homeownership accessible to millions of people who are currently priced out of the housing market.

2. Speed of Construction

Traditional construction can take months, if not years, to complete, depending on the size and complexity of the project. In contrast, 3D printing can significantly reduce the time needed to build a home. Some companies, like ICON and Apis Cor, have been able to print small homes in less than 24 hours. The fast turnaround means that homes could be constructed in a matter of days, not months.

This speed is particularly valuable in emergency situations, such as natural disasters. 3D printed homes could be deployed quickly to rebuild communities affected by earthquakes, floods, or hurricanes, providing people with safe and reliable shelter in record time.

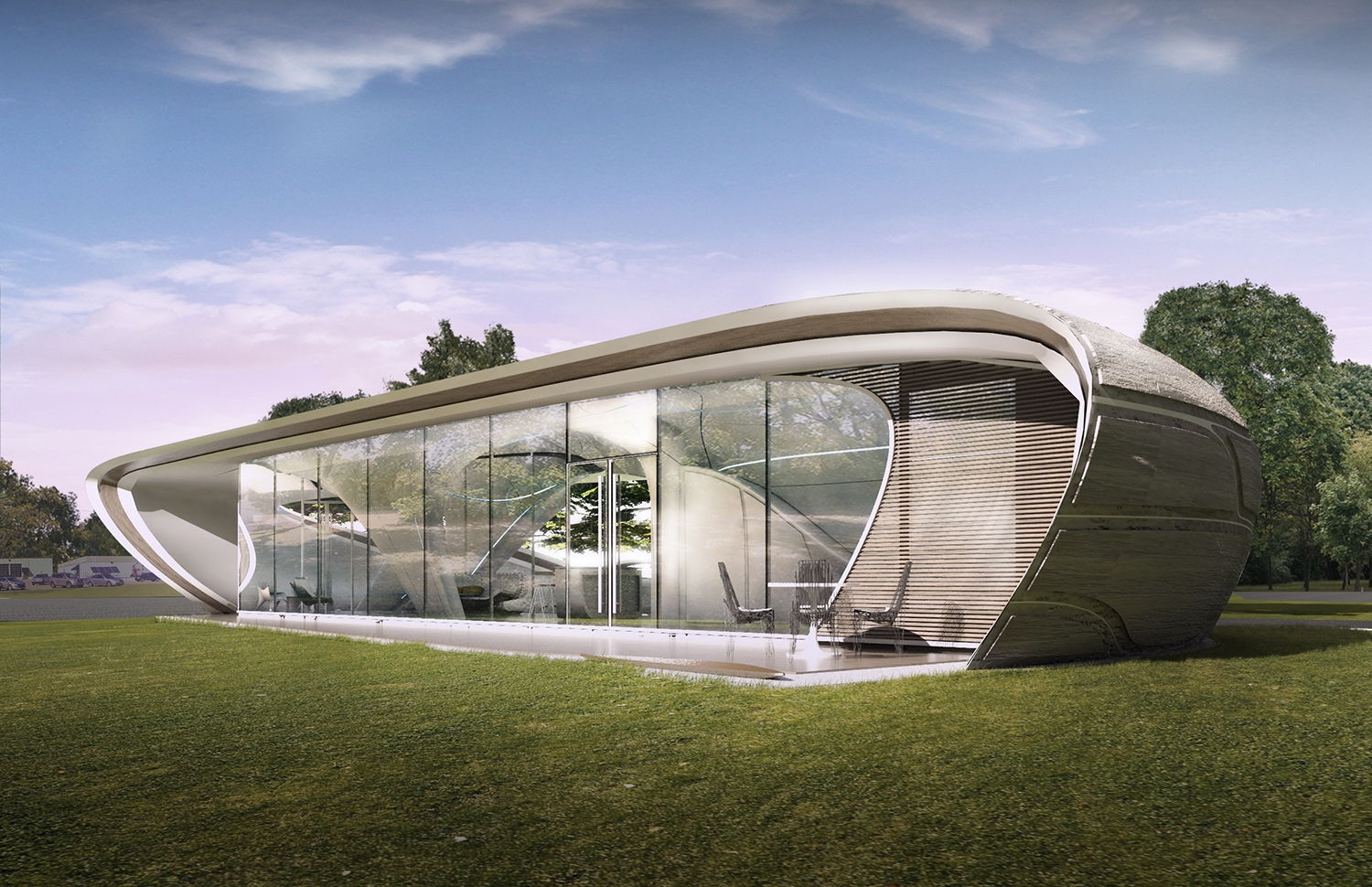

3. Customization and Design Flexibility

3D printing opens up a world of design possibilities that traditional construction simply cannot match. From curving walls and organic shapes to intricate details, 3D printing allows for highly customizable homes that fit the specific needs and preferences of homeowners.

Whether it’s a futuristic home with sculpted organic features or a more traditional design with personalized touches, the flexibility of 3D printing makes it possible to realize any vision. This is particularly advantageous for individuals who want unique, one-of-a-kind homes.

4. Sustainability and Eco-Friendliness

The construction industry is responsible for a significant amount of waste and environmental impact. Traditional building materials, like cement and wood, contribute to deforestation, pollution, and excessive carbon emissions. 3D printing, however, can use more sustainable materials, such as recycled plastics, or even earth-based compounds, significantly reducing the environmental footprint.

Furthermore, the precision of 3D printing means that only the necessary amount of material is used, resulting in minimal waste. The potential for using recycled materials also makes 3D printing homes a more eco-friendly alternative to conventional building techniques.

5. Durability and Safety

Many 3D printed homes are built with stronger, more resilient materials than those used in traditional construction. For example, 3D printed concrete homes can withstand extreme weather conditions, including hurricanes, earthquakes, and floods. The strength of these materials can also provide enhanced fire resistance, which is an essential safety feature in regions prone to wildfires.

The precise nature of 3D printing ensures that structural weaknesses caused by human error during construction are minimized. This could lead to safer, more durable homes that last longer than traditional houses.

Challenges and Limitations

Despite the numerous benefits of 3D printed homes, there are several challenges that need to be addressed before the technology becomes widespread.

1. Regulation and Building Codes

In many countries, building codes and regulations are not designed to accommodate 3D printing. This is a significant barrier to the widespread adoption of 3D printed homes, as regulatory approval is needed before any project can begin. In most cases, 3D printing is still viewed as a novel or experimental approach, and there is a lack of clear standards to govern its use.

However, some countries are beginning to revise their building codes to accommodate this new technology. For example, the United Arab Emirates has been at the forefront of embracing 3D printing in construction, with Dubai even planning to have 25% of its buildings 3D printed by 2030.

2. Material Limitations

While the materials used for 3D printing have come a long way, they are still limited in comparison to traditional construction materials. Most 3D printed homes rely on concrete, which may not always offer the same level of thermal insulation or aesthetic appeal as traditional brick or wood. Researchers are constantly working to develop new materials that are both stronger and more versatile for use in 3D printing, but these innovations will take time to fully materialize.

Furthermore, the durability of 3D printed homes in the long run is still somewhat unproven, especially when it comes to resistance against extreme environmental conditions over decades.

3. Scalability and Accessibility

While some 3D printed homes have been built successfully, scaling up the technology to build entire neighborhoods or cities is a different challenge altogether. Large-scale 3D printing requires substantial investment in infrastructure and machinery, which could be a barrier to entry for smaller construction firms or developing countries.

Additionally, the technology remains relatively expensive in its early stages. While costs are expected to decrease over time, 3D printing may not be affordable for all builders in the short term. The question remains whether the economies of scale can be realized quickly enough to make the technology widely accessible.

The Future of 3D Printed Homes

The potential of 3D printing in home construction is enormous. As the technology advances, it could redefine the way we think about housing. Imagine entire neighborhoods being built in a fraction of the time it takes today, with homes that are affordable, customizable, and environmentally friendly.

Moreover, as the world faces a growing housing crisis, particularly in urban areas, 3D printing could offer an innovative solution to the shortage of affordable homes. The ability to build homes rapidly and with minimal resources could help alleviate some of the pressure on the housing market, particularly in developing nations or disaster-stricken areas.

The future of 3D printed homes is not just about the technology itself, but how it intersects with the evolving needs of society. Whether it’s creating affordable housing in a crisis or rethinking urban design with sustainability in mind, 3D printing could help us build a new era of architecture—one that is smarter, more efficient, and more attuned to the planet’s needs.

Conclusion

3D printed homes may still seem like a radical concept, but the technology is evolving quickly, and its benefits—affordability, speed, customization, and sustainability—are too significant to ignore. While challenges like material limitations, regulatory hurdles, and scalability remain, the potential for 3D printed homes to revolutionize the housing industry is undeniable. As we continue to explore and develop this innovative technology, we may soon find that the home of the future is only a 3D printer away.