The traditional manufacturing industry has long been the backbone of many economies, offering stable jobs and fostering industrial growth. But in recent years, with the rise of automation, artificial intelligence, and globalization, the once-secure future of these jobs is increasingly in question. As technology advances at breakneck speed, it’s worth asking: are traditional manufacturing jobs in danger of extinction?

In this article, we’ll explore the current state of traditional manufacturing jobs, the threats they face, and the potential pathways for the industry’s future.

The Evolution of Manufacturing: From Handcraft to Automation

Manufacturing, as we know it, has undergone a significant transformation. At the beginning of the industrial revolution, factories employed large numbers of workers for tasks like weaving, metalworking, and assembling goods by hand. But as industries grew, mechanization became the driving force of production.

The advent of mass production, powered by machines and assembly lines, created more jobs and increased the scale of production. In the mid-20th century, traditional manufacturing jobs, including those in automotive factories, textiles, and electronics, were highly sought after. These jobs often promised long-term security, decent wages, and career growth for workers.

However, this golden era of manufacturing was not meant to last forever.

The Rise of Automation and Robotics

Automation is perhaps the most significant factor driving the transformation of the manufacturing industry. Today, robots and machines are capable of performing tasks that were once solely within the realm of human workers. From the assembly line to warehouse logistics, automation has revolutionized production efficiency.

For example, in the automotive industry, robots now assemble cars with precision and speed that would be difficult for human workers to match. Automated machines can work 24/7, with minimal downtime, reducing production costs and increasing output. This trend is not limited to just the automotive sector. Robotics and AI are now being integrated into industries like electronics, textiles, food processing, and even heavy machinery.

While automation has undoubtedly improved productivity and profitability, it has also led to the reduction of traditional manufacturing jobs. Lower-skilled, repetitive tasks are being replaced by machines, leading to significant job losses in certain sectors. According to a report by the McKinsey Global Institute, up to 800 million workers globally could be displaced by automation by 2030.

Globalization and Outsourcing: A Double-Edged Sword

While automation is a major contributor to the decline of traditional manufacturing jobs, globalization has played a crucial role as well. Over the past few decades, businesses have increasingly moved production overseas to take advantage of cheaper labor and fewer regulations. Countries in Asia, particularly China and India, have become global manufacturing hubs, offering low-cost labor and a growing middle class.

This shift has had a profound impact on job markets in developed economies, such as the United States and Western Europe. As companies moved production to countries where labor is cheaper, millions of manufacturing jobs were lost. The offshoring trend has led to the decline of industries that were once synonymous with the economic strength of nations, such as textiles, steel, and electronics.

Moreover, the rise of global supply chains has shifted the nature of manufacturing jobs. Many of the jobs that remain are now more specialized, requiring higher skill levels in areas like logistics, quality control, and machinery maintenance. Low-skilled, repetitive roles have been outsourced to other parts of the world, leaving workers in high-wage countries to face the pressures of unemployment or wage stagnation.

The Skills Gap: A Growing Challenge for the Workforce

Another critical factor in the future of traditional manufacturing jobs is the growing skills gap. While some manufacturing jobs have disappeared, others have evolved to require more technical expertise. Today’s manufacturing workforce needs to have a deep understanding of technology, robotics, and data analytics to keep up with the modern demands of the industry.

Unfortunately, many workers who have spent years honing traditional skills are finding it difficult to transition to these new roles. The skills required to operate sophisticated machinery or work with automation systems are often not taught in traditional manufacturing training programs. This has created a mismatch between the skills that employers need and the skills that the existing workforce possesses.

The skills gap is particularly evident in advanced manufacturing sectors like aerospace, electronics, and automotive, where workers must be proficient in both traditional craft and new technological tools. Bridging this gap will require significant investment in education and training programs that can prepare workers for the jobs of the future.

Reshoring: The Return of Manufacturing Jobs?

While traditional manufacturing jobs are being lost in many regions, some experts believe that a trend known as “reshoring” may provide a solution. Reshoring refers to the process of bringing manufacturing back to a country from overseas, often driven by factors like rising labor costs abroad, the desire for more control over supply chains, and advancements in automation that make domestic production more cost-effective.

In recent years, there have been signs that reshoring is gaining momentum. According to the Reshoring Initiative, U.S. companies announced more than 260,000 jobs had been reshored in 2020 alone. Many of these jobs are in high-tech industries, such as robotics, semiconductor manufacturing, and electric vehicles. While this is a positive development, it’s important to note that these new manufacturing jobs often require a different skill set than traditional roles.

Reshoring does not necessarily mean a return to the “good old days” of mass, low-skilled labor. Instead, the jobs that are coming back tend to be more specialized, high-tech positions that require expertise in advanced manufacturing techniques.

The Future of Traditional Manufacturing Jobs: Survival, Adaptation, or Extinction?

So, are traditional manufacturing jobs in danger of extinction? The answer is not as simple as a yes or no. Traditional manufacturing jobs, particularly those that rely on manual labor and repetitive tasks, are indeed at risk of disappearing. Automation and robotics have already displaced many of these jobs, and the trend is expected to continue.

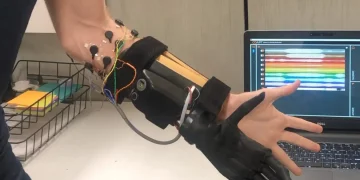

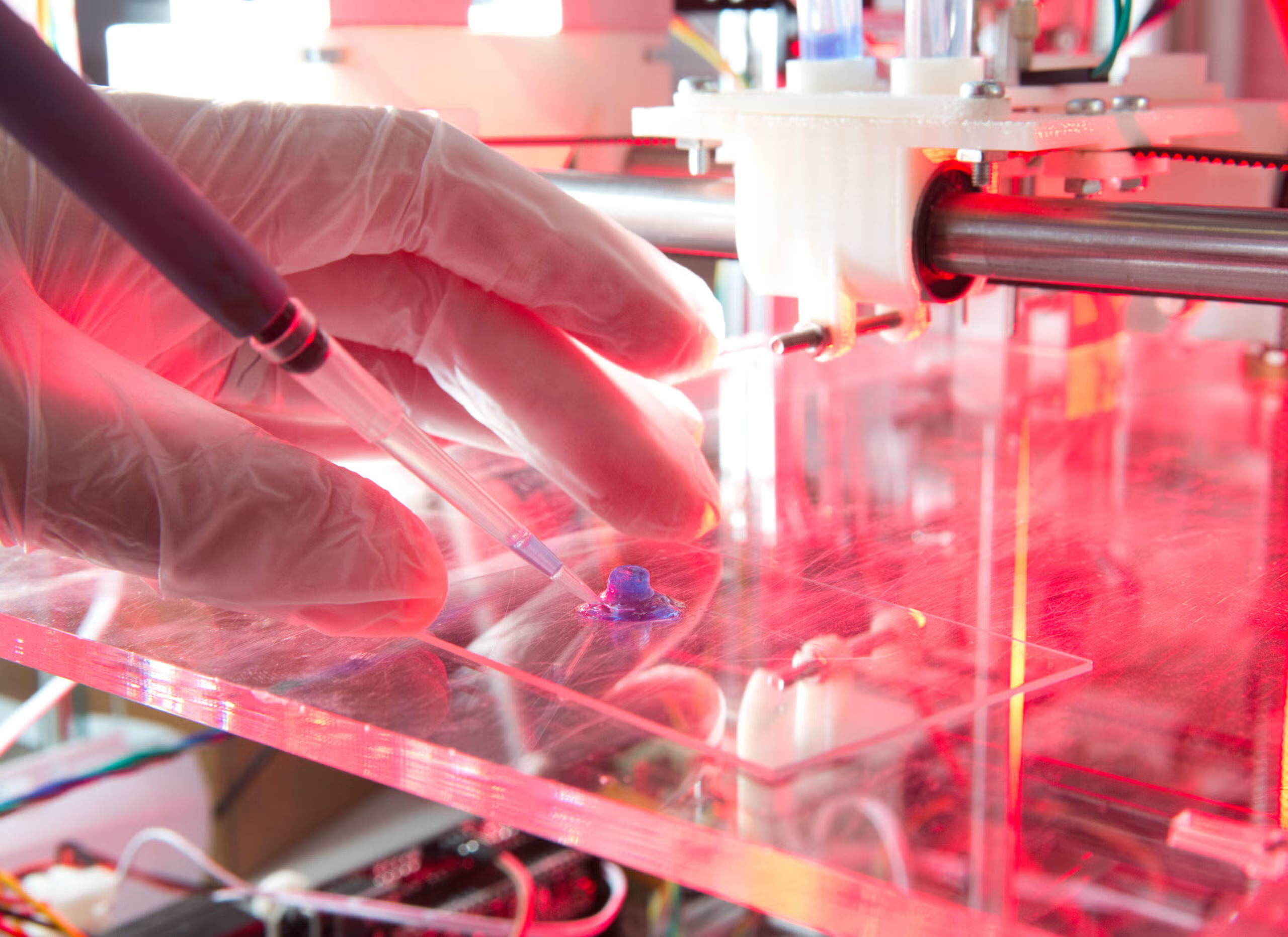

However, this doesn’t mean the end of manufacturing altogether. Instead, it marks a shift in the types of manufacturing jobs that will remain in demand. While automation is transforming the nature of work, it also opens up new opportunities for skilled workers. Industries that embrace new technologies like 3D printing, artificial intelligence, and advanced robotics will need highly skilled employees to manage, maintain, and optimize these systems.

Moreover, there are certain niches in manufacturing where traditional jobs may continue to thrive, such as artisan crafts, luxury goods, and industries that prioritize customization over mass production. As consumer demand for personalized and high-quality products grows, there could be a resurgence of interest in skilled craftsmanship.

Ultimately, the survival of traditional manufacturing jobs will depend on how the workforce and industry leaders adapt. Governments, businesses, and educational institutions must collaborate to provide the necessary training and resources to upskill workers. With the right investment in education, retraining programs, and a focus on innovation, traditional manufacturing jobs could evolve rather than disappear entirely.

Conclusion: Embracing Change While Preserving Tradition

The future of traditional manufacturing jobs is inextricably linked to the rapid advancement of technology. As automation, artificial intelligence, and globalization reshape the industry, many traditional roles will inevitably be displaced. However, the disappearance of these jobs does not necessarily signal the end of manufacturing in its entirety.

Instead, the key to preserving a sustainable manufacturing workforce lies in adapting to these changes. Embracing new technologies, reskilling workers, and focusing on high-tech, high-skill manufacturing processes can ensure that the industry remains a vital part of the economy for years to come. By finding a balance between innovation and tradition, we can help create a future where manufacturing jobs are not extinct but transformed to meet the demands of a rapidly changing world.