The rapid advances in artificial intelligence (AI) and robotics are changing the landscape of industries worldwide. These transformative technologies are not just enhancing productivity—they’re revolutionizing the way we design, manufacture, and deliver products and services. But the question arises: will AI and robotics truly power the future of industry, or are they merely buzzwords on the path to inevitable change? Let’s explore how these technologies are reshaping the industrial world, their potential impact, and the challenges that come with integrating them into the workforce.

The Industrial Revolution 4.0: A New Era

The term “Industry 4.0” refers to the fourth industrial revolution, where automation, AI, and data exchange play a central role in manufacturing and other industries. While the first industrial revolution harnessed steam power, and the second relied on electricity and mass production, the third focused on digital automation and information technology. The fourth, however, merges the physical, digital, and biological worlds through the integration of AI and robotics.

AI and robotics are at the heart of this transformation. From intelligent robots that can autonomously assemble products to AI-driven systems that predict machinery breakdowns before they happen, these technologies are reshaping industries in profound ways.

AI in Industry: The Brain Behind Automation

At its core, AI is about creating machines that can think, learn, and make decisions without human intervention. In industrial settings, AI is being leveraged in various forms:

Predictive Maintenance

One of the most significant uses of AI in industry is predictive maintenance. Traditional maintenance models often rely on scheduled repairs or reactive responses to breakdowns, leading to unplanned downtime and increased costs. However, AI can analyze real-time data from sensors embedded in machinery to predict when a machine is likely to fail, enabling companies to perform maintenance just before it’s needed. This proactive approach can significantly reduce costs and downtime, extending the lifespan of expensive equipment.

Quality Control

AI-powered vision systems are now being used for quality control in manufacturing processes. These systems employ machine learning algorithms to identify defects and anomalies in products at a much higher speed and precision than human inspectors. Not only does this reduce human error, but it also ensures that only high-quality products leave the production line, leading to improved customer satisfaction and fewer returns.

Supply Chain Optimization

AI is transforming supply chain management by optimizing inventory levels, predicting demand fluctuations, and automating order fulfillment. By analyzing massive datasets, AI systems can forecast future demand with remarkable accuracy, helping companies adjust production schedules, minimize waste, and deliver products to customers faster and more efficiently.

Robotics in Industry: The Hands of Automation

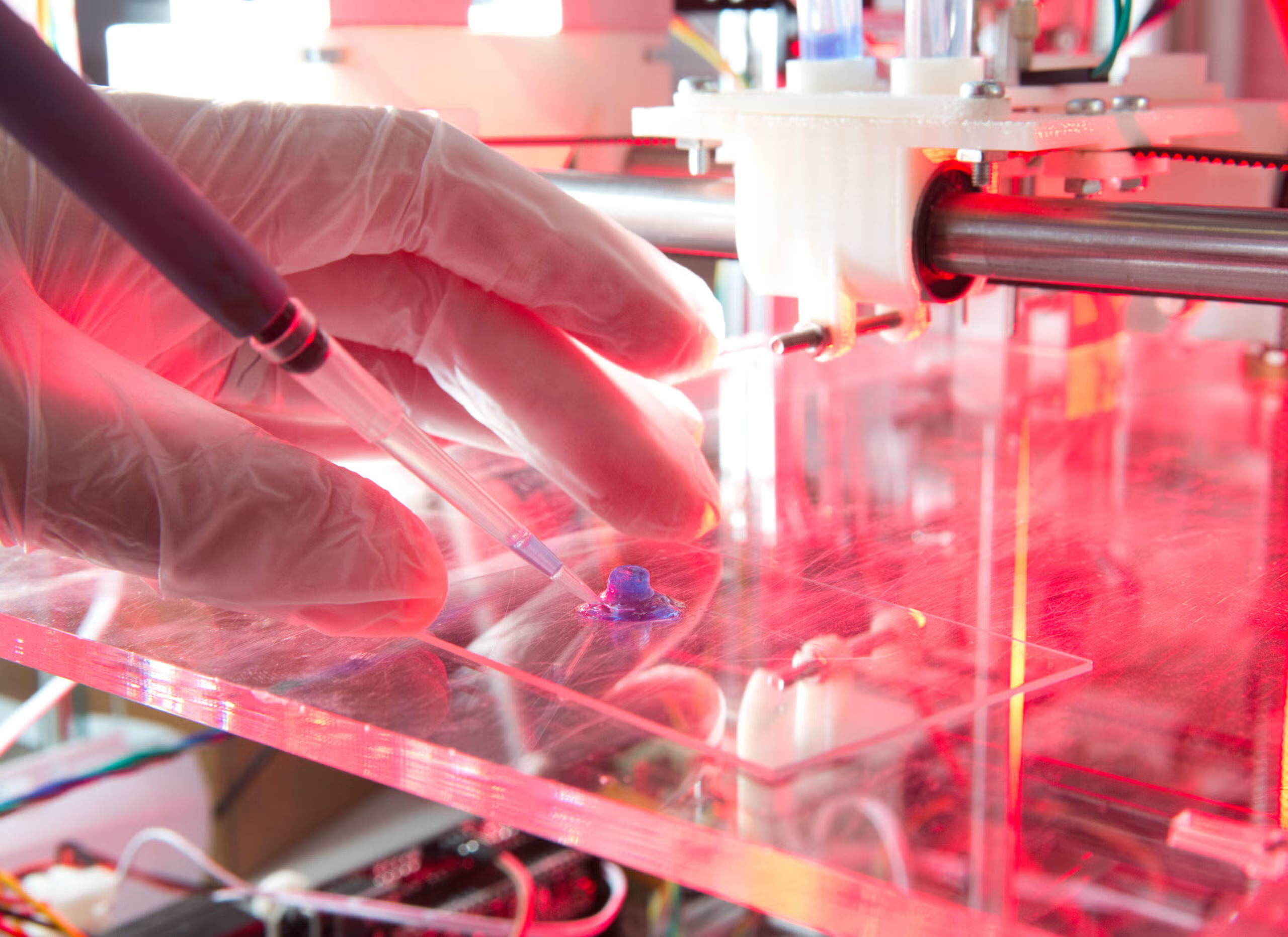

Robots, once limited to performing repetitive and simple tasks, have evolved into highly sophisticated machines capable of performing complex and delicate operations. In industrial environments, robots are increasingly integrated into production lines, logistics, and even research and development.

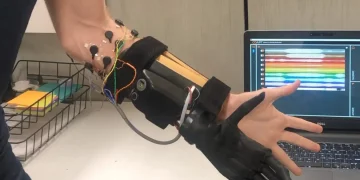

Collaborative Robots (Cobots)

One of the most exciting developments in robotics is the rise of collaborative robots, or “cobots.” These robots are designed to work alongside humans, assisting with tasks that require strength, precision, or repetition. Unlike traditional industrial robots, which operate in isolation within safety cages, cobots are equipped with sensors and AI algorithms to ensure safe interaction with human workers.

For example, in automotive manufacturing, cobots are used to perform tasks like assembling components, tightening screws, or painting parts—tasks that are physically demanding or require high levels of precision. By working side-by-side with human workers, cobots reduce strain and increase productivity, all while maintaining a safe working environment.

Autonomous Mobile Robots (AMRs)

Another breakthrough in robotics is the use of autonomous mobile robots (AMRs) in logistics. These robots are designed to navigate warehouses and factories autonomously, transporting goods from one location to another. Equipped with AI-driven navigation systems, AMRs can avoid obstacles, choose optimal routes, and work alongside human workers in dynamic environments.

AMRs are especially useful in e-commerce and distribution centers, where the demand for fast, efficient order fulfillment is ever-growing. They can pick and transport products, load delivery trucks, or move raw materials to different parts of the factory floor, reducing labor costs and improving efficiency.

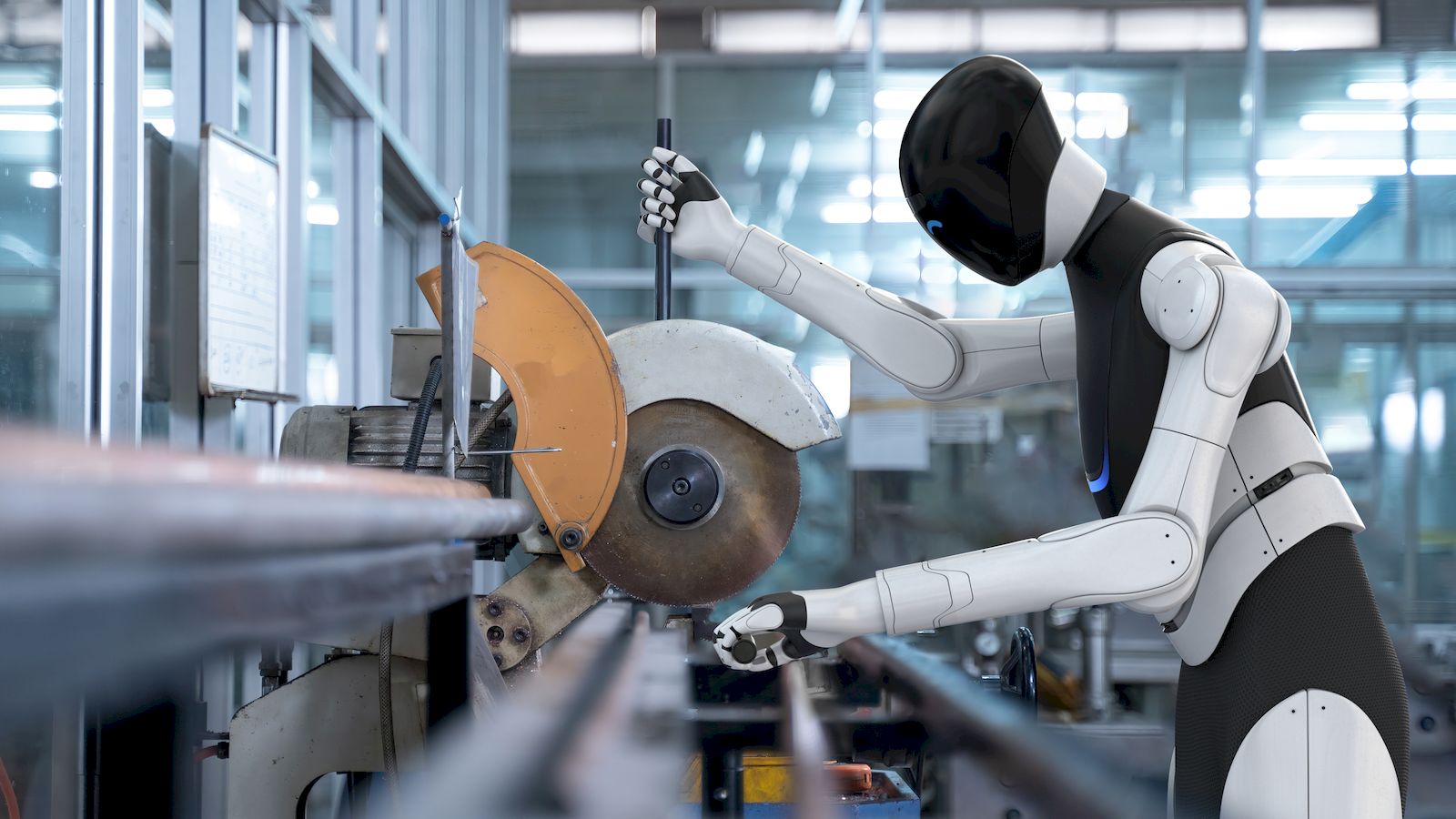

Industrial Robots: Automation on Steroids

In traditional manufacturing, industrial robots are designed to perform highly specialized tasks—such as welding, painting, or assembling components—with extreme precision and speed. The integration of AI has further enhanced their capabilities. Modern industrial robots can now adapt to changing environments, learn new tasks, and communicate with each other in real-time, creating fully automated production lines.

The use of AI in industrial robots means they can be deployed in complex environments with minimal human intervention. For example, AI-driven robots in semiconductor manufacturing can detect defects on microchips, adjust manufacturing parameters in real time, and even diagnose issues without the need for human oversight.

AI and Robotics: The Synergy for Industry

While AI and robotics can stand alone in transforming industry, their true potential is unlocked when they work together. The integration of AI and robotics allows machines to not only perform tasks but also learn and improve over time. This synergy is enabling the creation of autonomous production lines where robots and AI systems collaborate seamlessly, increasing efficiency, reducing waste, and improving product quality.

For example, in advanced manufacturing plants, AI-powered robots can adjust production schedules based on real-time data, ensuring that production lines run smoothly. They can detect and correct issues as they arise, reducing the need for human intervention. Additionally, the data collected by robots can be fed into AI systems to continuously refine the manufacturing process, ensuring that products are consistently of the highest quality.

Challenges and Concerns

Despite the immense potential of AI and robotics, the widespread adoption of these technologies is not without its challenges. One of the most pressing concerns is the impact on the workforce. As robots and AI systems take on more complex and specialized tasks, many jobs—particularly those in manufacturing, logistics, and administration—may become obsolete. This raises the question of how industries can transition their workforces and provide retraining opportunities to workers displaced by automation.

Moreover, the integration of AI and robotics into industries requires significant investment in infrastructure and training. Companies must also navigate potential cybersecurity risks, as interconnected machines and AI systems could be vulnerable to hacking and data breaches.

Another challenge is the ethical implications of AI and robotics. As machines become more autonomous, questions arise about accountability and decision-making. If a robot makes a mistake that leads to an accident or injury, who is responsible? Similarly, the use of AI in decision-making processes—such as hiring or loan approvals—raises concerns about bias and fairness.

The Road Ahead: What Does the Future Hold?

As industries continue to embrace AI and robotics, we can expect to see even more significant changes in the coming years. The convergence of AI, robotics, and other emerging technologies such as 5G and the Internet of Things (IoT) will lead to smarter, more connected factories. These technologies will enable real-time monitoring, faster production cycles, and greater customization of products.

Moreover, the evolution of AI and robotics will likely lead to new business models and industries. For instance, the rise of autonomous delivery robots could create entirely new logistics companies, while AI-driven design tools might lead to innovations in product development.

While the future of industry may be powered by AI and robotics, it’s important to recognize that these technologies are tools—tools that need to be harnessed in a way that benefits both businesses and workers. The key will be ensuring that AI and robotics are integrated responsibly, with consideration given to ethical, social, and economic implications.

Conclusion: The Dawn of a New Industrial Revolution

AI and robotics are not just a passing trend—they are the driving forces behind the next industrial revolution. With the potential to enhance efficiency, improve safety, and create new business opportunities, these technologies will undoubtedly shape the future of industries around the world. However, this transformation is not without its challenges. Businesses, governments, and society as a whole must work together to ensure that the benefits of AI and robotics are shared widely and that the workforce is prepared for the changes ahead.

The future of industry will likely be one where humans and machines work side by side, leveraging the strengths of both to achieve greater heights of productivity and innovation. The question is not whether AI and robotics will power the future of industry, but how we will harness these technologies to create a future that benefits everyone.