Introduction

In the ever-evolving landscape of industrial production, the term “smart factory” has rapidly gained momentum. As industries across the globe strive to increase efficiency, cut costs, and stay competitive, the integration of cutting-edge technologies like the Internet of Things (IoT), Artificial Intelligence (AI), and robotics is transforming traditional manufacturing operations. Smart factories, characterized by interconnected systems, automation, and real-time data analytics, promise to revolutionize how products are designed, produced, and delivered.

But, are smart factories truly the new norm in manufacturing? Let’s explore the technological advancements driving this transformation, the benefits of smart factories, and the challenges they bring. We’ll also take a closer look at their real-world applications and what the future holds for this disruptive innovation.

What Defines a Smart Factory?

A smart factory is not merely a factory that uses machines or automation—it’s an entire ecosystem that integrates advanced technologies to create a highly efficient, self-optimizing environment. Key characteristics of a smart factory include:

1. Connectivity

Smart factories rely on robust, reliable connectivity systems. This means machines, devices, and production lines are all connected through sensors and networks, allowing for real-time monitoring and data collection.

2. Automation

Automation plays a pivotal role in smart factories. Robotics, AI-driven systems, and machine learning algorithms are employed to streamline production processes, minimize human intervention, and reduce errors.

3. Data Analytics

In a smart factory, the vast amounts of data generated from machines, sensors, and systems are analyzed to optimize production cycles. Predictive analytics help identify potential failures before they occur, preventing downtime and improving productivity.

4. Flexibility

Smart factories are highly adaptable. Thanks to automated systems, they can quickly adjust to changes in production demands, custom orders, or shifts in market trends.

5. Sustainability

Efficiency isn’t just about speed or cost-saving—it also incorporates sustainability. Smart factories often utilize energy-efficient solutions and optimize resource usage to reduce waste, water usage, and energy consumption.

The Key Technologies Driving Smart Factories

A handful of technological innovations are central to the operation of a smart factory:

1. Internet of Things (IoT)

IoT refers to the network of interconnected devices that communicate with one another. In a smart factory, IoT enables seamless data exchange between machines, tools, and sensors. This continuous flow of data allows manufacturers to monitor every stage of the production process and respond instantly to issues.

For example, IoT sensors can monitor equipment health in real time. If a machine shows signs of wear and tear, maintenance teams can be alerted immediately, preventing unplanned downtime.

2. Artificial Intelligence and Machine Learning

AI and machine learning (ML) algorithms analyze data collected from IoT sensors and other sources to make informed decisions about production processes. AI models can optimize production schedules, predict equipment failures, and even design products.

In the case of predictive maintenance, machine learning algorithms analyze historical data to identify patterns that indicate when a machine is likely to break down. This predictive capability reduces maintenance costs and improves the overall reliability of the factory.

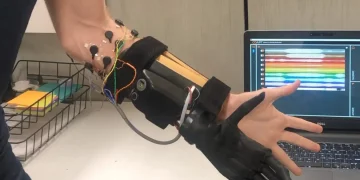

3. Robotics and Automation

Robotic systems are a cornerstone of smart factories. Automated robots perform repetitive and labor-intensive tasks with precision and speed, reducing human error and increasing throughput.

Additionally, robots equipped with AI and machine learning capabilities can adapt to different tasks, further enhancing their flexibility. Collaborative robots (cobots) are designed to work alongside human workers, complementing their skills and improving overall efficiency.

4. Digital Twins

A digital twin is a virtual replica of a physical asset or system. In a smart factory, digital twins allow for the simulation and monitoring of production lines, machinery, or even entire factories. This digital counterpart can be used to simulate various scenarios and predict outcomes, helping manufacturers optimize processes and improve efficiency before making costly changes to the physical environment.

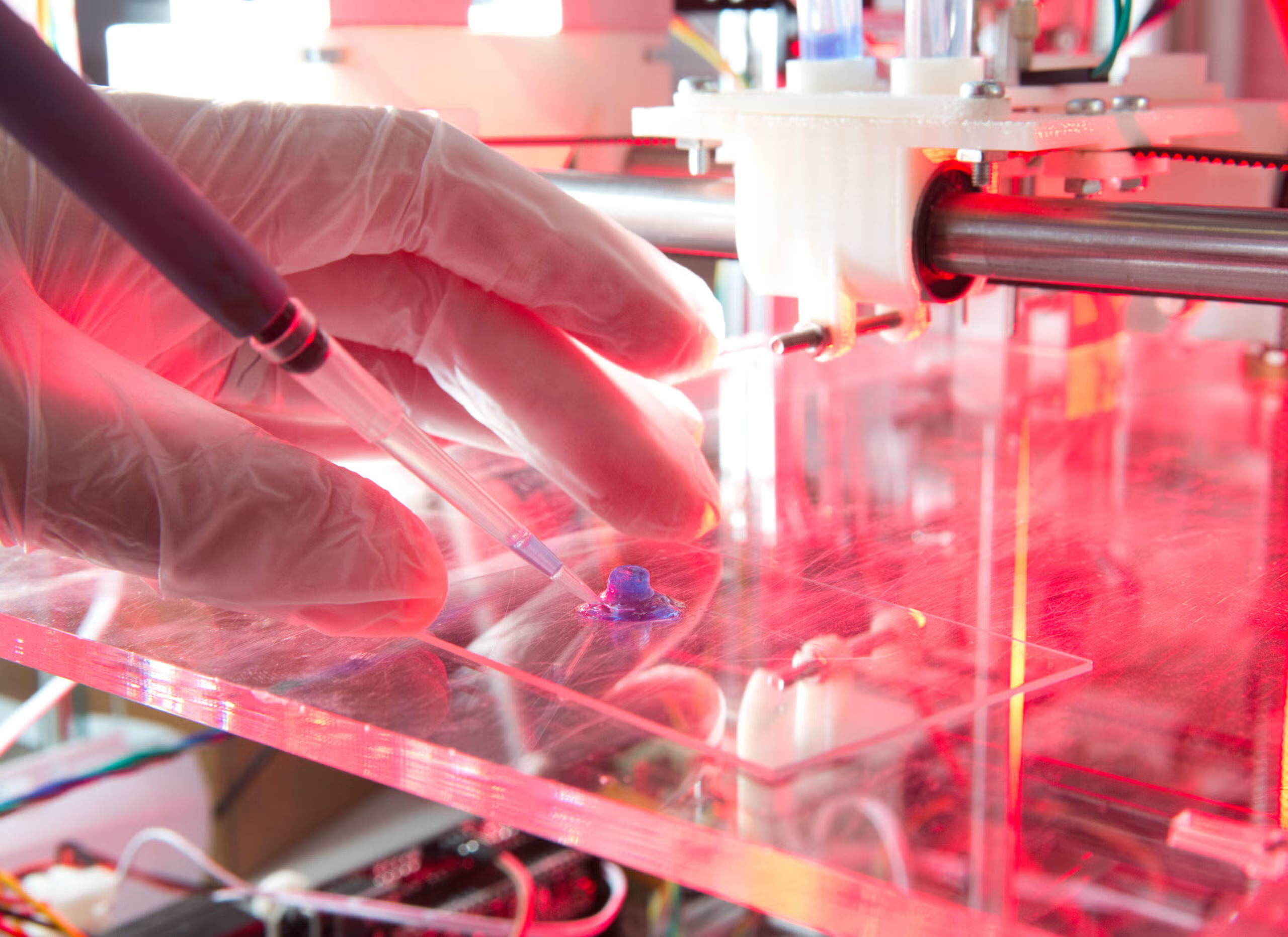

5. Additive Manufacturing (3D Printing)

3D printing is revolutionizing the production process, especially for customized or low-volume parts. By using digital models, manufacturers can create products layer by layer, reducing material waste and offering greater flexibility in design.

In smart factories, 3D printing can complement traditional manufacturing techniques. For instance, it can be used to produce prototypes or unique parts on-demand, reducing lead times and inventory costs.

Benefits of Smart Factories

As manufacturers embrace digital transformation, smart factories offer numerous advantages:

1. Increased Efficiency and Productivity

Automation and real-time data analytics significantly improve production efficiency. By reducing human error, optimizing workflows, and streamlining processes, manufacturers can achieve higher throughput with less waste.

For example, AI algorithms can optimize production schedules, ensuring that resources are used effectively and downtime is minimized. Additionally, predictive maintenance ensures that equipment is serviced before it breaks down, minimizing unplanned downtime.

2. Cost Reduction

While the initial investment in smart factory technologies can be substantial, the long-term savings are often significant. Automated systems reduce labor costs, and the optimization of energy usage and resource consumption leads to lower operational expenses.

Moreover, with advanced monitoring systems in place, manufacturers can better manage inventory and supply chains, reducing the costs associated with excess stock or stockouts.

3. Improved Product Quality

Smart factories can deliver higher product quality by minimizing human error, maintaining consistency, and ensuring that products meet exact specifications. Automated systems can continuously monitor quality and make real-time adjustments to production processes.

In some cases, AI-powered quality control systems can spot defects that the human eye might miss. This level of precision not only improves the final product but also reduces the need for costly rework.

4. Customization and Flexibility

Smart factories excel at handling customized orders. With flexible production lines and automated systems, manufacturers can easily adapt to changing customer demands, producing smaller batches of products with varying specifications.

For instance, a manufacturer of smartphones might offer customizable features, such as color, storage capacity, or even hardware configurations. The flexibility of smart factories allows for these variations to be produced efficiently without disrupting the overall production flow.

5. Enhanced Sustainability

Sustainability is becoming an increasingly important factor in manufacturing. Smart factories reduce energy consumption, optimize material usage, and minimize waste. AI algorithms help identify areas where energy use can be minimized, while digital twins allow manufacturers to simulate and test more sustainable practices before implementation.

Smart factories are also more efficient at recycling materials, reducing water usage, and managing waste, contributing to greener manufacturing processes.

Real-World Applications of Smart Factories

Smart factories are no longer a theoretical concept but a reality across various industries. Here are a few examples:

1. Automotive Industry

Automotive manufacturers have long embraced automation, and many are now integrating smart factory principles to further enhance efficiency. For example, Ford’s use of AI to optimize production schedules has resulted in faster manufacturing times. BMW uses smart factory technology to create customizable cars, allowing customers to personalize their vehicles during the production process.

2. Electronics Manufacturing

The electronics industry is another area where smart factories are gaining traction. Companies like Siemens are using digital twins and IoT sensors to monitor the production of circuit boards and other components. Smart factories enable rapid prototyping and design iterations, reducing time-to-market and improving product quality.

3. Food and Beverage

The food and beverage industry is leveraging IoT sensors and AI to improve food safety, reduce waste, and enhance production efficiency. For example, sensors can monitor the temperature and humidity of storage areas, ensuring optimal conditions for perishable goods. AI-driven systems optimize production schedules, reducing food waste due to overproduction or spoilage.

4. Textiles and Apparel

The textile industry is undergoing a transformation as manufacturers adopt smart factory solutions to address sustainability challenges. Companies like Adidas are using 3D knitting machines that produce garments with minimal waste. These machines are part of a larger effort to create a more sustainable and efficient supply chain.

Challenges in Implementing Smart Factories

Despite the numerous benefits, there are several challenges to adopting smart factory technologies:

1. High Initial Investment

The cost of implementing smart factory technologies can be a significant barrier, especially for small and medium-sized enterprises (SMEs). The integration of AI, robotics, and IoT systems requires substantial upfront investment in hardware, software, and infrastructure.

2. Cybersecurity Risks

As smart factories rely heavily on interconnected systems, cybersecurity becomes a critical concern. A single cyberattack could disrupt production, steal sensitive data, or damage equipment. Manufacturers must invest in robust cybersecurity measures to protect their operations.

3. Skill Gaps

The introduction of advanced technologies requires a workforce that is skilled in areas like data analytics, robotics, and AI. Companies may face challenges in finding employees with the necessary expertise, and training existing staff can be time-consuming and expensive.

4. Integration with Legacy Systems

Many manufacturers still rely on legacy systems that are not compatible with newer smart technologies. Integrating these old systems with new technologies can be complex and costly, requiring extensive customization.

The Future of Smart Factories

The future of smart factories looks incredibly promising. As technology continues to evolve, manufacturers will have access to even more powerful tools to enhance production processes. The integration of 5G networks, for example, will provide faster data transmission, enabling real-time communication between machines and systems across vast distances.

We can also expect to see even greater advances in AI and machine learning, allowing for more sophisticated predictive maintenance, quality control, and process optimization. As more manufacturers embrace smart factory solutions, we may see the emergence of entirely new business models, with greater collaboration and decentralization across supply chains.

Conclusion

Smart factories are quickly becoming a standard in the manufacturing sector, offering numerous benefits, including enhanced efficiency, cost savings, improved product quality, and greater sustainability. While challenges like high initial investment and cybersecurity risks exist, the advantages of smart factories are hard to ignore. As technology advances, we can expect the smart factory concept to expand, ushering in a new era of manufacturing.