In a world where resource depletion, waste management, and sustainability are increasingly at the forefront of global discourse, industries face growing pressure to innovate and adapt. One of the most promising solutions to these mounting challenges is the concept of the Circular Economy. But can it truly revolutionize industries across the globe and save them from the brink of environmental collapse? This article explores the potential of the circular economy to transform global industries, drive sustainability, and foster a future that balances economic growth with environmental responsibility.

Understanding the Circular Economy: A Game-Changer

At its core, the circular economy is a systemic approach to sustainability. Unlike the traditional linear economy — where resources are extracted, used, and then discarded as waste — the circular economy operates on the principle of keeping products, materials, and resources in use for as long as possible. The model focuses on reducing waste, reusing materials, recycling products, and regenerating natural systems.

Key Principles of the Circular Economy

- Design for Longevity: Products should be designed to last longer, be easily repaired, and have a longer lifecycle.

- Maintain and Extend the Life of Products: Through repair, maintenance, and refurbishment, products can remain functional and useful beyond their initial use phase.

- Recover and Regenerate Resources: Materials from discarded products are recovered and reused to create new products, minimizing waste and the need for virgin resources.

- Business Model Transformation: Companies shift from selling products to providing services such as leasing, take-back schemes, or product-as-a-service (PaaS), which reduces consumption and waste.

The Industrial Revolution 4.0: Circular Economy at the Forefront

The industrial landscape is in the midst of a revolution. Digital technologies, artificial intelligence (AI), and automation are transforming industries, and the circular economy is becoming a key component of this transformation. While many industries still adhere to the traditional “take, make, dispose” model, companies across various sectors are recognizing the potential of circular principles to increase profitability while addressing pressing environmental challenges.

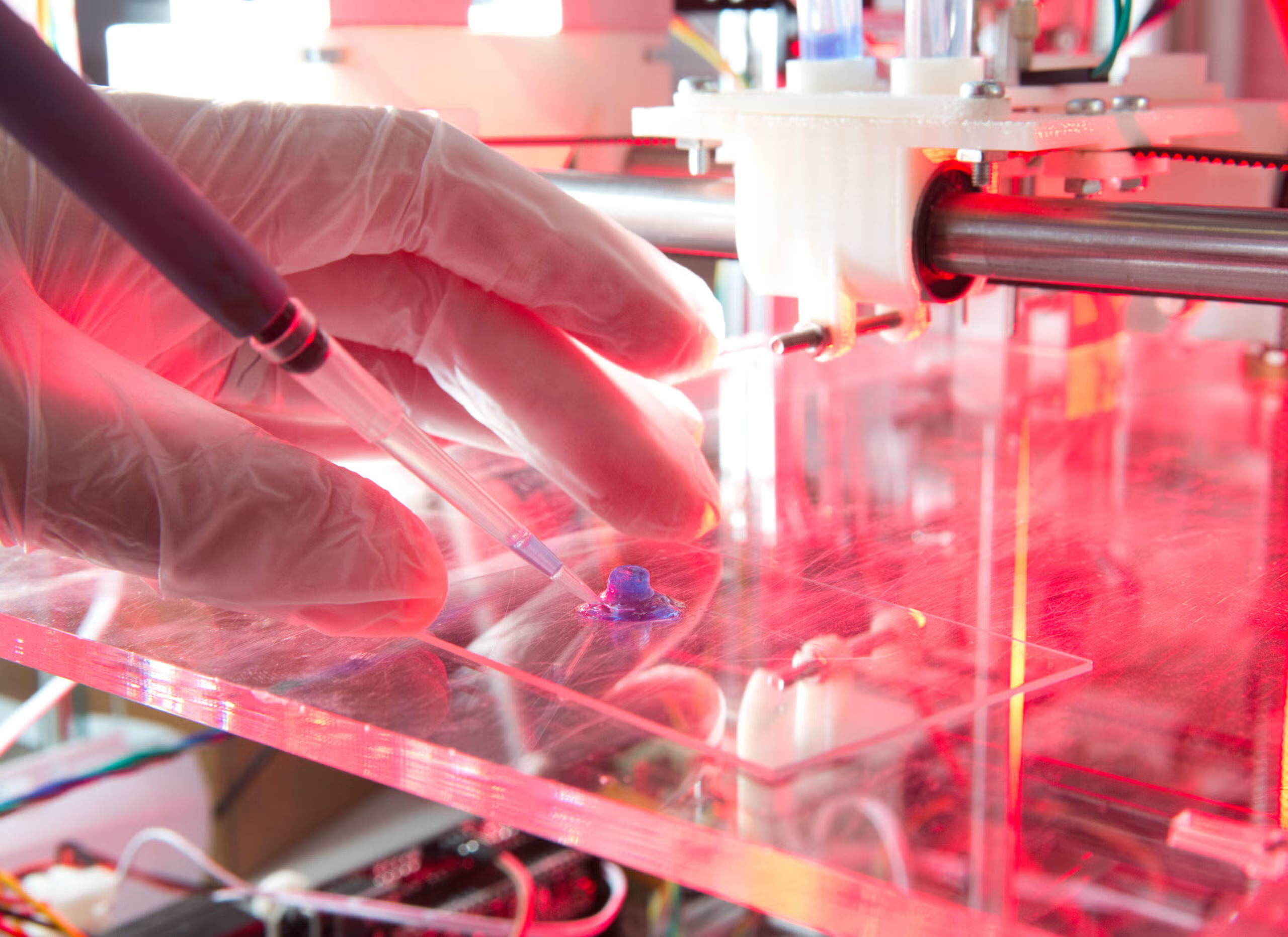

Circular Economy in Manufacturing: Redefining Product Lifecycles

Manufacturing is one of the most resource-intensive sectors. From raw materials extraction to the production of finished goods, the process often results in significant waste generation and high carbon emissions. In response, companies are rethinking how products are designed and produced.

For instance, companies like Philips and Interface are leading the way by incorporating circular principles into their manufacturing processes. Philips, with its “Circular Lighting” program, offers lighting-as-a-service, where they maintain ownership of the lighting systems they install in buildings. When the lights no longer work, they are refurbished and reused, extending their lifecycle and reducing waste.

Interface, a global leader in modular flooring, has committed to using 100% recycled and bio-based materials in its products, aiming for a future where its products do not contribute to landfill waste. By creating closed-loop systems, these companies are reducing their reliance on virgin materials and enhancing product longevity.

Circular Economy in the Fashion Industry: A Sustainable Makeover

The fashion industry is one of the most significant contributors to global waste, with billions of garments ending up in landfills each year. However, as sustainability becomes a key priority, the circular economy offers a pathway for fashion companies to reduce waste, minimize resource consumption, and ensure that garments remain in use longer.

Leading brands like Patagonia, Levi’s, and H&M are integrating circular practices into their business models. Patagonia, for example, promotes its “Worn Wear” program, where customers can buy, sell, or trade used Patagonia gear. This program encourages consumers to repair and reuse rather than discard items. Additionally, Levi’s has introduced a line of jeans made from organic cotton and has committed to using recycled materials in its production processes.

H&M’s Conscious Collection promotes the use of sustainable materials and offers a garment recycling program where customers can drop off their old clothes in exchange for store discounts. Through these initiatives, the fashion industry is taking important steps toward reducing waste and creating a more sustainable, circular model.

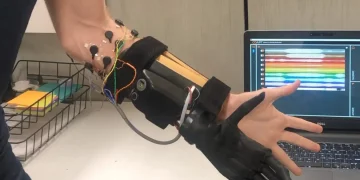

Circular Economy in the Technology Sector: Redefining the Digital Future

The technology sector is another key area where the circular economy can have a significant impact. With the rapid growth of e-waste — electronic products that have reached the end of their useful life — recycling and reusing materials from old electronics is becoming increasingly important. Precious metals, such as gold, silver, and copper, are often discarded during the disposal process, but they can be recovered and repurposed through circular systems.

Apple is one of the pioneers in this space, implementing its “Daisy” robot to disassemble old iPhones and recover valuable materials for reuse in new devices. The company is also working toward a closed-loop supply chain, where all materials used in production are sourced from recycled products. This approach not only reduces the environmental impact of electronics manufacturing but also helps address the global problem of e-waste.

Other tech giants like Dell and HP are also embracing circular economy practices, ensuring that products are designed for easy disassembly and recycling, and offering take-back programs for old equipment.

Circular Economy in the Automotive Industry: Driving Change

The automotive industry is undergoing a transformation, driven by both technological advancements and shifting consumer demands for sustainability. With the rise of electric vehicles (EVs) and autonomous cars, the need to rethink the lifecycle of vehicles and their components is greater than ever.

Many automakers, such as BMW and Volkswagen, are exploring ways to implement circular principles in their manufacturing processes. BMW’s “i3” electric car is designed with sustainability in mind, using recycled materials for various parts and offering a highly modular structure that can be easily repaired and refurbished. Additionally, Volkswagen is working to integrate circular economy principles into its battery manufacturing, aiming to create a closed-loop system for EV battery materials.

The potential for circularity in the automotive sector goes beyond vehicle design; it extends to the reuse and recycling of car parts, including tires, engines, and even batteries. As the industry accelerates its transition to electric vehicles, the adoption of circular economy practices will be critical in reducing the carbon footprint of production and ensuring that resources are used more efficiently.

Challenges to Implementing the Circular Economy

Despite the promising potential of the circular economy, several barriers remain to its widespread adoption. One of the primary challenges is the need for substantial investment in infrastructure. Recycling facilities, product refurbishment centers, and systems for collecting used materials are often lacking or inefficient. Without the proper infrastructure, the transition to a circular economy becomes more difficult and costly.

Another challenge is the mindset shift required by businesses and consumers. Traditional linear models have been deeply ingrained in industries for decades, and companies may resist adopting circular practices due to perceived cost barriers or concerns about short-term profits. Consumers, too, must change their attitudes toward consumption, embracing ideas like sharing, repairing, and reusing products rather than continually purchasing new ones.

Furthermore, regulatory frameworks and government policies must evolve to support the circular economy. Clear regulations and incentives are needed to encourage businesses to adopt sustainable practices and create a level playing field for circular innovations.

The Future of the Circular Economy: A Sustainable and Profitable Path Forward

Despite these challenges, the future of the circular economy looks promising. As global awareness of environmental issues grows, consumers are demanding more sustainable products, and governments are introducing policies that promote circularity. According to the World Economic Forum, the circular economy could unlock $4.5 trillion in economic opportunities by 2030, providing a significant incentive for industries to embrace this new way of thinking.

Industries that successfully transition to circular business models will not only benefit from increased resource efficiency and reduced waste but also from stronger brand loyalty, lower operational costs, and greater resilience in the face of resource scarcity. In turn, the circular economy can drive economic growth while also safeguarding the planet for future generations.

By fostering innovation, collaboration, and sustainable practices, industries across the globe have the opportunity to thrive in the age of circularity. The question is no longer whether the circular economy can save industries — it’s how fast can we adapt to it, and how far can it take us.