Introduction: Understanding Industry 4.0

Industry 4.0 represents a seismic shift in how we design, manufacture, and distribute goods. It builds upon earlier industrial revolutions, adding advanced digital technologies to automation processes. The goal is to create “smart” factories—systems that can communicate with each other, learn from data, and make autonomous decisions to increase efficiency, reduce costs, and improve safety.

At the heart of Industry 4.0 lies Artificial Intelligence (AI)—the capability of machines to simulate human-like cognitive functions such as learning, reasoning, problem-solving, and even creativity. The integration of AI within industrial environments isn’t just a trend—it’s a paradigm shift. But is AI truly the key to unlocking the potential of Industry 4.0?

Let’s explore this in-depth.

What is Industry 4.0?

Before diving into the role of AI, let’s briefly define Industry 4.0. The term originated in Germany and describes the fourth industrial revolution. It signifies a fusion of advanced technologies like the Internet of Things (IoT), artificial intelligence, big data, robotics, and cloud computing, all working together to transform manufacturing processes.

The primary focus of Industry 4.0 is connectivity and automation—machines and devices connected in an ecosystem that can exchange data and make decisions in real-time, often without human intervention. This ecosystem requires systems that can:

- Monitor and analyze processes

- Predict maintenance needs

- Make decisions based on real-time data

- Self-optimize production schedules

- Reduce waste and improve efficiency

As these technologies evolve, AI becomes an indispensable tool. But why?

The Role of AI in Industry 4.0

AI plays several critical roles within the broader framework of Industry 4.0:

- Predictive Maintenance: AI-powered systems can predict equipment failures before they occur, minimizing downtime and reducing costly repairs. By analyzing data from sensors embedded in machines, AI can spot early signs of wear and tear, helping prevent unplanned outages.

- Process Optimization: Through machine learning algorithms, AI can continuously analyze production lines and identify inefficiencies. For example, AI can suggest changes to workflows, material usage, or energy consumption to optimize performance. By learning from past data, it can make decisions that improve both the speed and quality of production.

- Supply Chain and Inventory Management: AI enhances logistics and supply chain management by analyzing vast amounts of data to predict demand, track inventories, and optimize delivery schedules. By anticipating fluctuations in demand, AI can automate restocking, ensuring manufacturers always have the right materials at the right time.

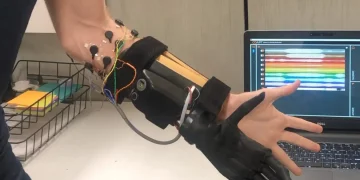

- Autonomous Systems and Robotics: Robots powered by AI are increasingly being used in factories to perform tasks such as assembly, painting, welding, or even sorting. These robots can adapt to changes in the environment, communicate with other machines, and even make decisions about how best to perform a task. As they “learn” from each operation, these robots become more efficient over time.

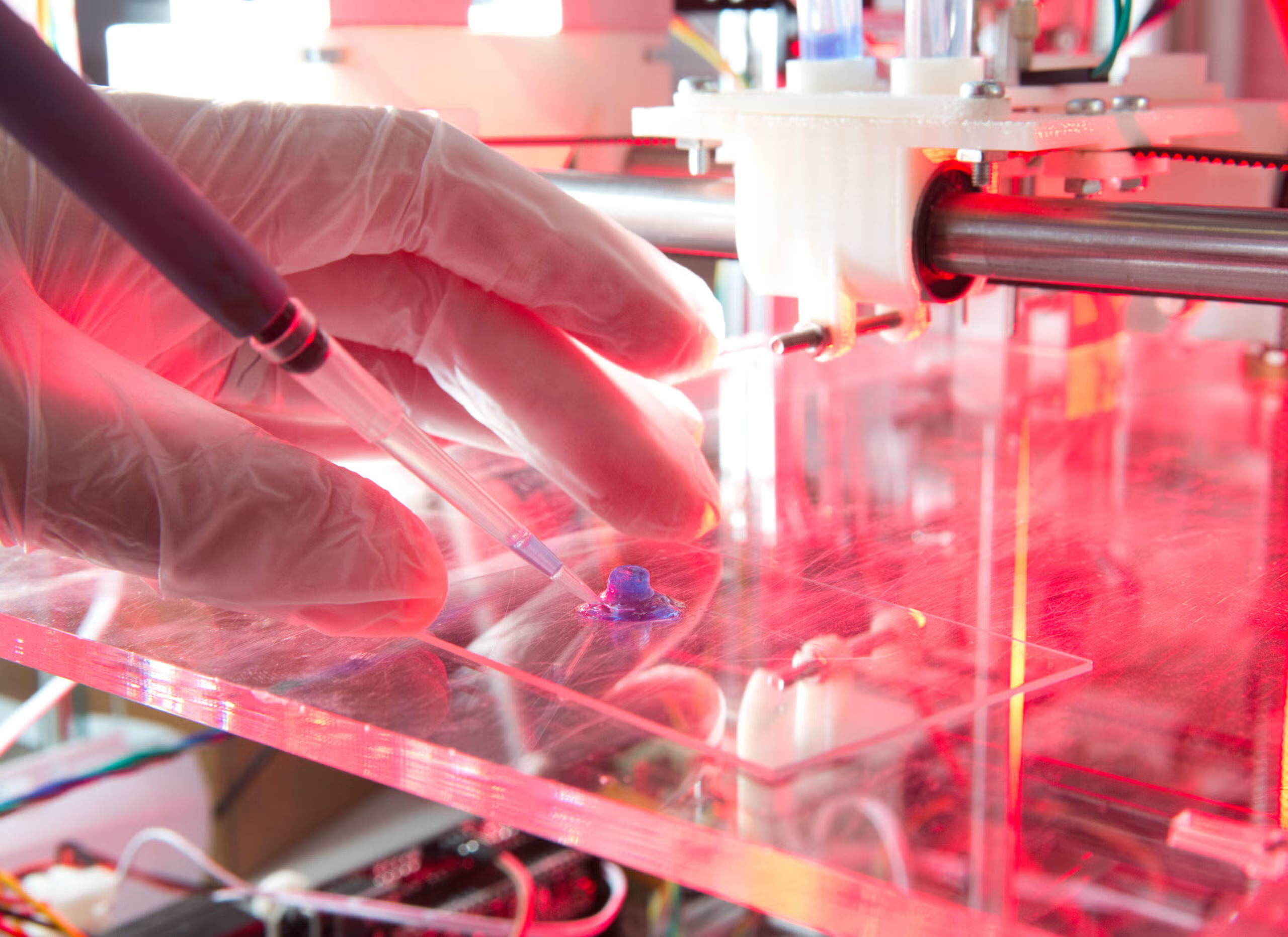

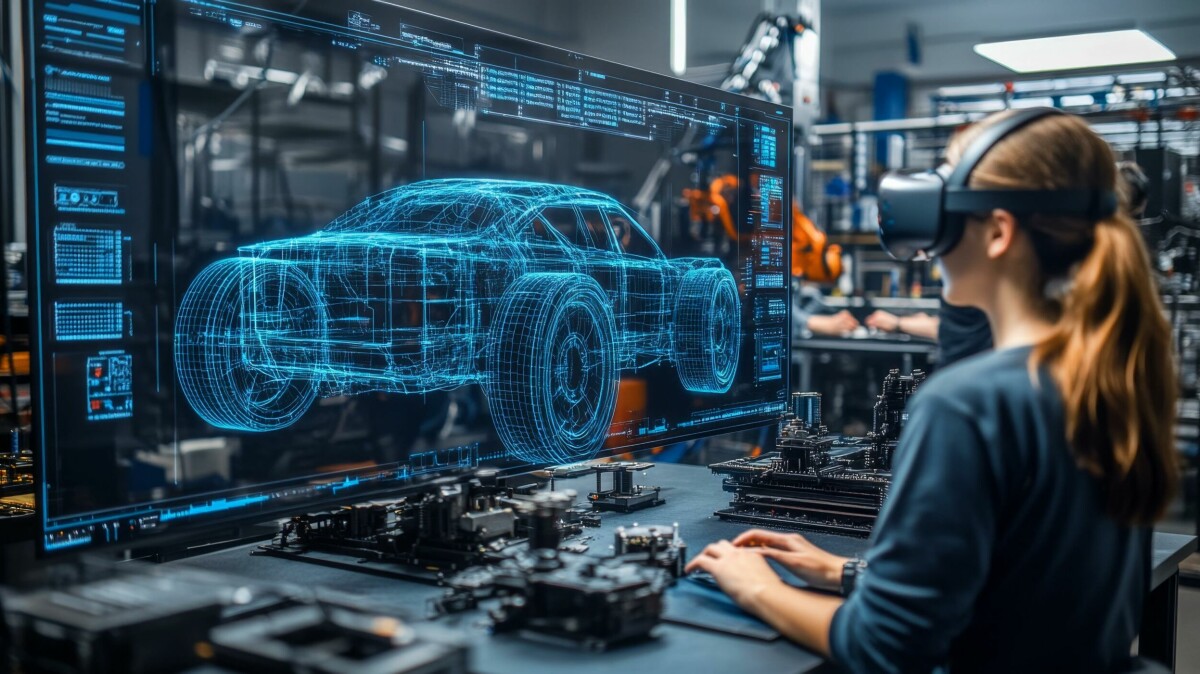

- AI in Design and Prototyping: AI is not only transforming how things are made, but also how they are designed. Generative design, powered by AI, allows manufacturers to input certain parameters (such as material strength, weight, and cost) and generate multiple design options. These designs are often more efficient and innovative than those produced by human designers alone.

AI’s Impact on the Workforce

One of the most debated aspects of Industry 4.0 is its impact on the workforce. As machines become more intelligent, will humans be replaced? The short answer is not necessarily. While AI is automating many routine tasks, it is also creating opportunities for humans to focus on higher-level functions.

In fact, AI has the potential to:

- Augment Human Workers: AI systems can handle repetitive tasks, freeing human workers to focus on complex problem-solving, decision-making, and creative activities. This results in more value-driven roles for employees.

- Create New Roles: The rise of AI in manufacturing leads to a demand for skilled workers who can develop, maintain, and optimize AI systems. Fields like data science, machine learning, and robotics are becoming increasingly essential.

- Improve Safety: AI-powered robots can take over dangerous tasks, reducing human exposure to hazardous environments. In industries such as mining, chemicals, and heavy manufacturing, this can be life-saving.

Despite concerns about job displacement, it’s clear that AI will require a shift in skills—towards a more tech-savvy, data-driven workforce. The real challenge is ensuring that workers are trained for these new roles and that automation doesn’t lead to widening inequality.

AI and Data in Industry 4.0: The Big Data Connection

The backbone of AI in Industry 4.0 is data. Industrial machines generate vast amounts of data that, when analyzed, can unlock valuable insights. But this data alone isn’t enough. AI systems need access to high-quality, real-time data to function effectively.

Here’s how data and AI work together in an Industry 4.0 context:

- Data-Driven Decision Making: AI systems can analyze enormous datasets in real-time to make decisions with incredible speed and accuracy. In manufacturing, this means AI can adjust production lines based on shifting demands, changing input costs, or new customer orders without human intervention.

- AI for Process Simulation: Data-driven AI can simulate production processes under different scenarios, enabling manufacturers to identify the most efficient methods and optimize workflows before they’re implemented on the factory floor.

- IoT and AI Integration: The Internet of Things (IoT) involves connecting sensors and devices to the internet to gather and transmit data. In a smart factory, AI analyzes this IoT data to monitor equipment performance, detect anomalies, and optimize processes in real time.

- Data-Driven Customization: AI enables manufacturers to analyze consumer data to create personalized products or adjust production processes based on customer preferences. This level of customization enhances customer satisfaction and boosts sales.

The Challenges of Implementing AI in Industry 4.0

While the potential benefits of AI in Industry 4.0 are immense, there are also several challenges that companies face when implementing these systems:

- Data Privacy and Security: With the massive amounts of data generated by AI systems comes the risk of data breaches and cyberattacks. Ensuring the privacy and security of this data is a top priority for businesses that want to avoid reputational damage and legal ramifications.

- Integration Complexity: Many companies have legacy systems that aren’t designed to communicate with modern AI technologies. Integrating new AI systems with older equipment and processes can be both expensive and technically challenging.

- Skill Gaps: The successful implementation of AI requires a highly skilled workforce. Finding workers who are proficient in AI, machine learning, and data science can be difficult, particularly in industries with low levels of tech literacy.

- Cost of Implementation: For small and medium-sized enterprises (SMEs), the upfront investment in AI technologies and the infrastructure needed to support them can be a significant barrier. However, as AI tools become more affordable, this challenge may become less pressing.

Future Trends: AI and Beyond in Industry 4.0

As Industry 4.0 continues to evolve, AI will be just one part of a larger, interconnected technological ecosystem. Here are a few trends to watch:

- Edge Computing: Instead of sending data to centralized cloud systems, edge computing allows data to be processed closer to its source (i.e., on the factory floor). This will speed up decision-making and reduce the latency issues often associated with cloud computing.

- 5G Connectivity: With the advent of 5G networks, manufacturers will be able to transmit data faster and more reliably, enabling real-time communication between machines, systems, and AI algorithms.

- Blockchain for Supply Chains: Blockchain technology could further enhance the transparency and security of AI-driven supply chains by creating immutable records of transactions and data exchanges.

- AI-Driven Sustainability: AI will play a significant role in creating sustainable manufacturing processes by optimizing energy use, reducing waste, and ensuring efficient resource management.

Conclusion: AI—The Backbone of Industry 4.0?

While Industry 4.0 is undoubtedly a multi-faceted phenomenon, AI is undeniably at its core. From predictive maintenance to autonomous robots, AI has the potential to revolutionize how industries operate, leading to smarter, more efficient, and more flexible production environments.

However, the implementation of AI comes with its challenges. To truly unlock its potential, businesses must address issues like data privacy, security, and workforce skills. Moreover, the successful integration of AI into existing infrastructures will require careful planning, investment, and a long-term vision.

Industry 4.0 is more than just a technological evolution—it’s a revolution in the way we work, produce, and live. AI is one of the most powerful drivers of this change, and its influence will only continue to grow. For companies willing to embrace it, the future looks bright, with endless possibilities for innovation, growth, and transformation.