As we stand at the precipice of a technological revolution, one question that reverberates through the corridors of industries across the world is: Is the future of industry digital or analog? The clash between these two paradigms isn’t merely philosophical—it’s practical, shaping the way companies operate, innovate, and evolve. As we hurtle into an era dominated by automation, data, and connectivity, it’s crucial to explore how these forces are affecting industries traditionally rooted in analog systems, and whether they will eventually give way entirely to the digital revolution—or if the two will find a harmonious coexistence.

The Digital Dawn: From Industry 1.0 to 4.0

The Industrial Revolution marked the advent of mechanization, introducing machines powered by steam and later electricity. But the digital revolution—often referred to as Industry 4.0—has altered the landscape in ways that previous innovations never could. Industry 4.0 brings cyber-physical systems, Internet of Things (IoT), and smart technologies to the forefront, promising to redefine the way businesses produce goods, deliver services, and engage with customers.

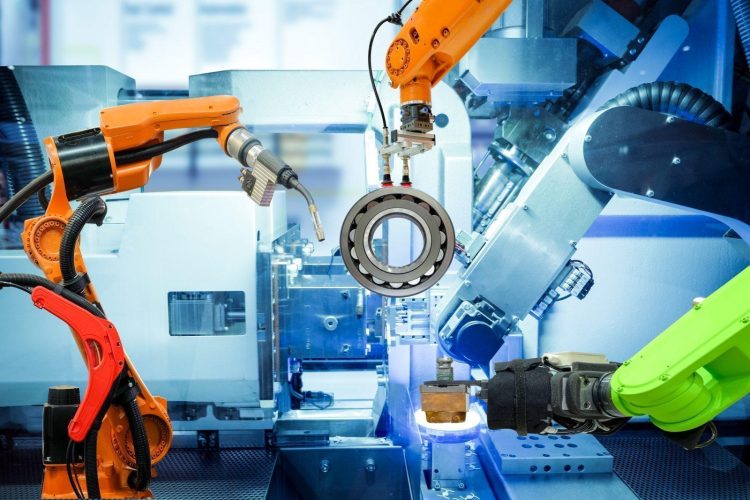

- Automation: One of the primary characteristics of Industry 4.0 is the rise of automation. Robots, powered by artificial intelligence (AI) and machine learning, are transforming manufacturing processes by taking over tasks that once required human dexterity and decision-making. This transition towards digital systems allows for higher precision, scalability, and efficiency than was ever possible with traditional, analog machinery.

- Data-Driven Decisions: At the heart of this digital revolution is big data. By connecting devices, machines, and systems to the internet, industries are collecting vast amounts of real-time data. Companies can now analyze this data to improve decision-making, predict maintenance needs, optimize supply chains, and even create personalized customer experiences. This data-driven approach is far more efficient than any analog method of decision-making, which often relied on manual processes, intuition, or outdated information.

- Artificial Intelligence: AI is perhaps the most significant digital technology poised to transform industries. From self-learning algorithms that optimize production lines to machine vision systems that detect defects in real time, AI is revolutionizing industries like manufacturing, logistics, healthcare, and retail. The future of industry is one where digital intelligence not only supports operations but also predicts future trends and drives innovation.

Analog Legacy: The Enduring Appeal

Despite the overwhelming shift towards digital systems, there is an undeniable charm and practicality to analog technologies. Analog systems, while not as fast or data-driven, still have distinct advantages in certain industries. The question is, will analog systems fade into obscurity, or will they adapt and coexist alongside digital innovations?

- Simplicity and Reliability: One of the enduring strengths of analog technologies is their simplicity. Mechanical systems, such as traditional manufacturing machinery or basic control systems, tend to be easier to understand, troubleshoot, and repair. In certain industries, like aerospace or heavy machinery, where downtime can be extremely costly, the reliability and stability of analog systems are still crucial.

- Tactile Feedback: Analog systems often provide a level of tactile feedback that digital technologies cannot replicate. For example, the act of turning a physical knob or pressing a button on a traditional control panel can be deeply satisfying and intuitive, especially in environments where user interaction is crucial. For this reason, many industries that require precision and hands-on interaction, such as high-end audio or fine-tuned machinery, continue to favor analog solutions.

- Environmental Constraints: In some remote or rugged environments, where access to digital infrastructure is limited, analog systems offer a more practical solution. For example, communication systems in deep-sea exploration or space missions often rely on analog equipment for robustness and energy efficiency.

The Hybrid Approach: Blending the Best of Both Worlds

Rather than an absolute choice between digital and analog, the future of industry may well lie in hybrid solutions—a seamless integration of both worlds. As businesses strive to remain competitive, the need for flexibility and adaptability has never been more apparent. Digital technologies offer rapid, data-driven advantages, but analog systems still have irreplaceable value in certain contexts.

- Analog-Digital Convergence: Consider a smart factory where digital systems are deeply integrated into the production process. Sensors and IoT devices constantly monitor equipment performance, feed data into a central system for analysis, and trigger automated processes. Yet, alongside these high-tech systems, analog machinery could still play a role in specific tasks that demand unique qualities like durability or tactile feedback.

- Predictive Maintenance: In industries like manufacturing, where both digital and analog systems are in play, predictive maintenance is a key area where the two technologies converge. Digital systems can monitor the condition of analog machines, predicting potential failures before they happen, thus extending the lifespan of analog components and minimizing downtime.

- Smart Analog: Emerging innovations in the analog space are also bridging the gap with digital technologies. For instance, smart sensors—which combine analog circuitry with digital capabilities—are allowing for more accurate measurements and better integration with IoT systems. This innovation enables industries to harness the benefits of both worlds.

Impact on Key Industries

Manufacturing: Efficiency Meets Precision

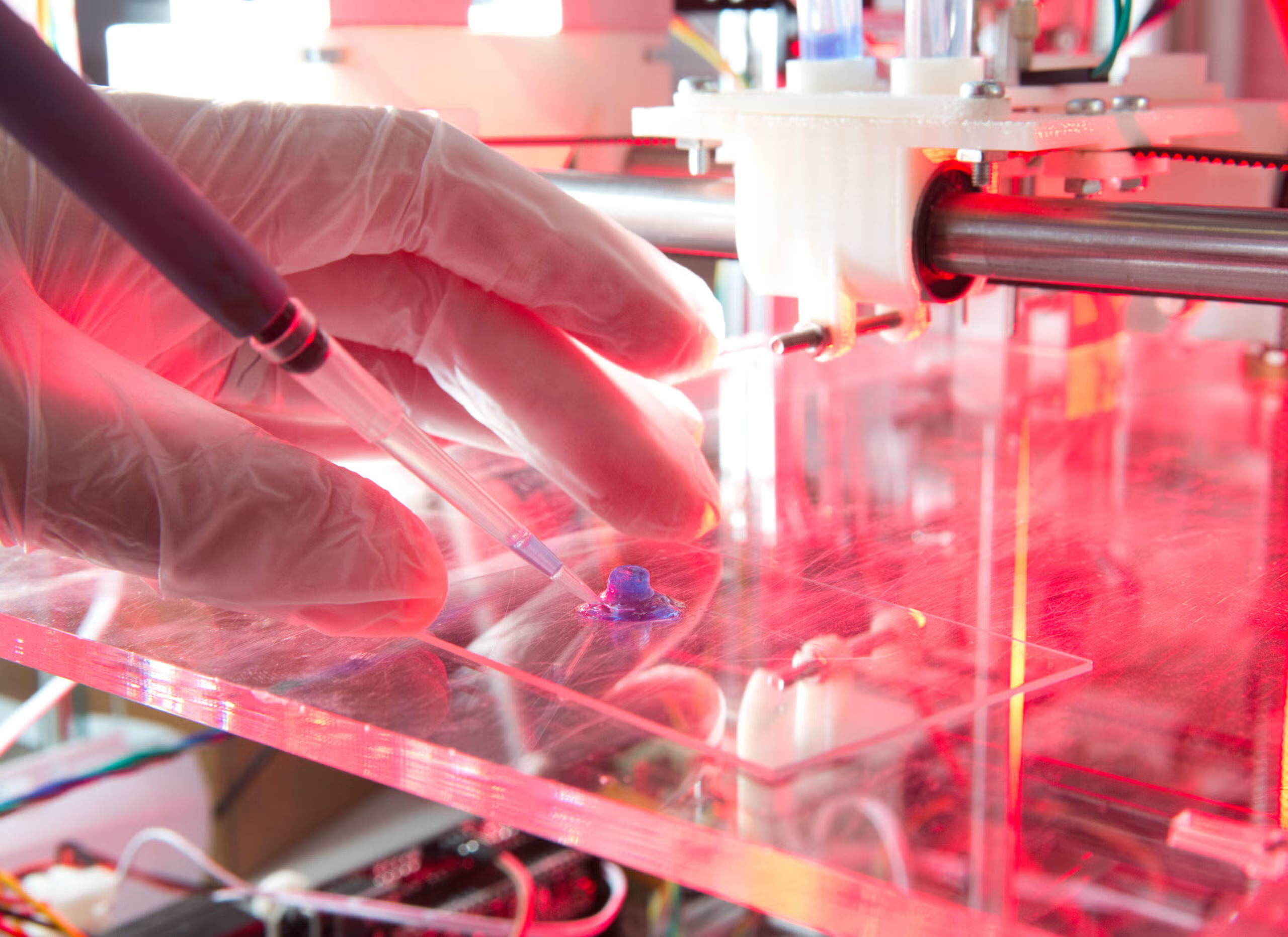

The manufacturing industry is perhaps the most affected by the rise of digital technologies. Digital tools such as 3D printing, additive manufacturing, and advanced robotics have completely transformed production methods. Where traditional methods required vast, sprawling factories, automation, and digital integration allow companies to build more compact, efficient production lines.

However, analog technologies remain integral in areas that require precision and care. For example, high-end machine tools, CNC (Computer Numerical Control) machines, and other fine-tuned devices still rely on a combination of digital and analog technologies to achieve the exact level of precision required for creating delicate components.

Healthcare: Digital Diagnostics and Analog Care

In healthcare, digital health technologies are revolutionizing patient care through telemedicine, digital records, and predictive analytics. However, analog tools like stethoscopes and traditional diagnostic equipment still play an essential role in clinical environments, providing tactile and auditory feedback that digital technologies cannot match.

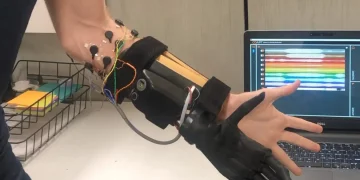

Moreover, in surgical procedures, a combination of robot-assisted surgery and skilled human input remains crucial. The surgeon’s hand, aided by analog tools, complements the precision of the digital robotic assistant. In the future, we may see augmented reality (AR) and virtual reality (VR) technologies further bridging the gap, allowing digital interfaces to guide analog procedures.

Energy: From Fossil to Renewable

The energy sector provides an interesting case study in the tension between analog and digital. The transition from fossil fuels to renewable energy sources like solar and wind power is, in itself, a digital transformation. Smart grids and digital monitoring systems are critical for optimizing energy distribution, reducing waste, and integrating renewable sources into the grid.

At the same time, analog systems such as manual turbines, mechanical generators, and traditional pumps continue to operate, especially in remote or off-grid locations where digital infrastructure is impractical.

Transportation: Autonomous and Analog

The transportation sector is undergoing an intense shift toward autonomous vehicles powered by digital technologies such as machine learning, sensor networks, and AI algorithms. While the future of self-driving cars is undeniably digital, analog systems remain a staple in vehicle control systems, engines, and many safety-critical components that are not yet fully automated.

Conclusion: A Future Defined by Adaptability

The future of industry is not a binary choice between digital and analog technologies. Instead, it will be shaped by the adaptability of industries to integrate both, leveraging the strengths of each. Digital technologies will continue to push industries towards greater efficiency, precision, and connectivity. However, analog technologies will remain relevant, offering reliability, simplicity, and tactile interaction that digital systems can’t always replicate.

As industries evolve, the hybrid model—combining the best of digital innovation with the enduring strengths of analog systems—will likely define the future. It’s a future where both worlds coexist, complementing each other to create more robust, flexible, and efficient systems across all sectors.