Introduction

As the world becomes increasingly aware of the environmental challenges posed by industrial growth, the question arises: Can manufacturing truly be green? The traditional manufacturing sector has long been a significant contributor to environmental degradation, from carbon emissions to excessive waste. However, with rapid advancements in technology and increasing pressure for sustainability, the future of manufacturing holds the potential for a major shift. This shift could transform how we produce goods—making it not just efficient but eco-friendly.

But the question remains: Are we truly on the path to sustainable manufacturing, or is it just another buzzword to appease environmental concerns? To answer this, we must explore the current state of manufacturing, the technologies reshaping it, and the challenges ahead.

The Current State of Manufacturing

Traditional manufacturing has long been associated with significant environmental costs. Consider this: the global manufacturing sector is responsible for around 20-30% of global greenhouse gas emissions. Factories are energy-intensive, consuming vast amounts of electricity, gas, and water. Materials used in manufacturing often come from unsustainable sources, and waste generation is a major issue. To make matters worse, the linear “take, make, dispose” model still dominates, where products are created, used, and discarded without regard for their life cycle.

For instance, in the production of electronics, precious metals like gold, silver, and copper are extracted, processed, and often discarded after a product’s short life cycle. This not only contributes to deforestation and mining pollution but also results in large amounts of electronic waste, or e-waste, which is notoriously difficult to recycle.

However, things are beginning to change. The rising awareness of environmental sustainability, coupled with emerging green technologies, suggests that the future of manufacturing may not be as grim as it seems. To understand this shift, let’s dive into some of the most promising trends in green manufacturing.

Emerging Trends in Green Manufacturing

In recent years, green technologies and sustainable production methods have emerged as game-changers in the manufacturing sector. Let’s look at a few of the most influential developments.

1. Green Technologies and Energy Efficiency

One of the most significant trends is the adoption of energy-efficient technologies. The integration of renewable energy sources like solar, wind, and even geothermal energy is slowly gaining momentum within factories. By shifting away from fossil fuels, manufacturers are reducing both their carbon footprint and their operational costs. For example, Tesla’s Gigafactory is primarily powered by solar energy, contributing significantly to its sustainability goals.

Moreover, energy-efficient production processes, such as LED lighting, smart HVAC systems, and advanced machinery that reduces energy consumption, are increasingly common. In fact, energy audits and smart meters are helping manufacturers better understand their energy consumption and optimize accordingly.

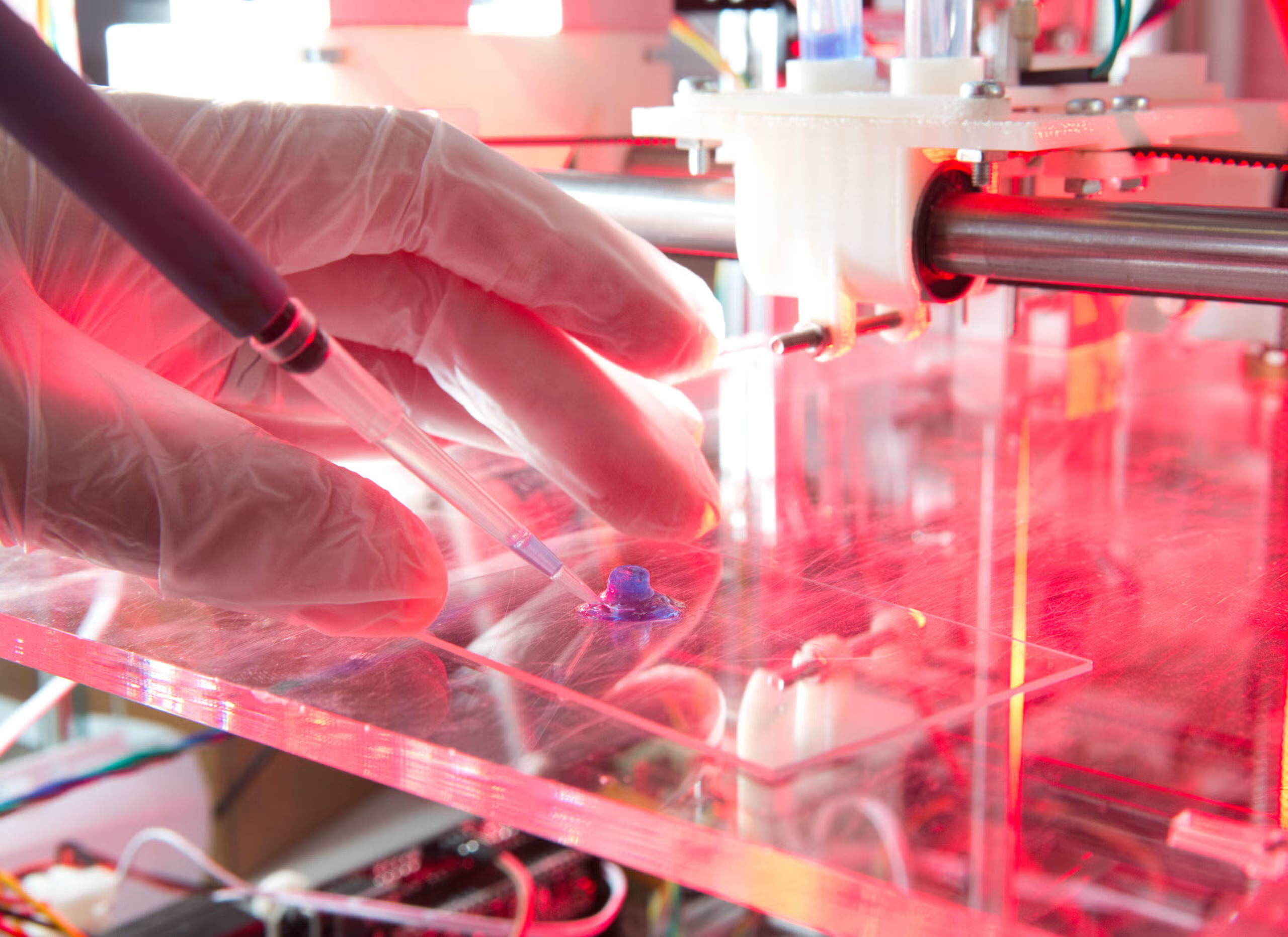

2. 3D Printing and Additive Manufacturing

The rise of 3D printing has the potential to revolutionize the manufacturing industry. Unlike traditional manufacturing methods that often involve subtracting materials from a larger block (thus generating waste), 3D printing builds objects layer by layer, using only the materials needed for the object’s structure. This significantly reduces waste and lowers energy consumption. Additionally, the ability to use biodegradable or recycled materials in 3D printing enhances its sustainability credentials.

3. Circular Economy

The circular economy concept focuses on designing products and systems that minimize waste and make use of resources as long as possible. In a circular system, materials are reused, refurbished, and recycled to extend their lifecycle. Apple, for example, has committed to using 100% recycled materials in its products, and its Liam robot is capable of disassembling iPhones to recover valuable materials like gold and cobalt.

Additionally, manufacturers are increasingly adopting closed-loop systems in which waste materials are fed back into the production process rather than being discarded. This not only conserves resources but also reduces the overall environmental impact of manufacturing.

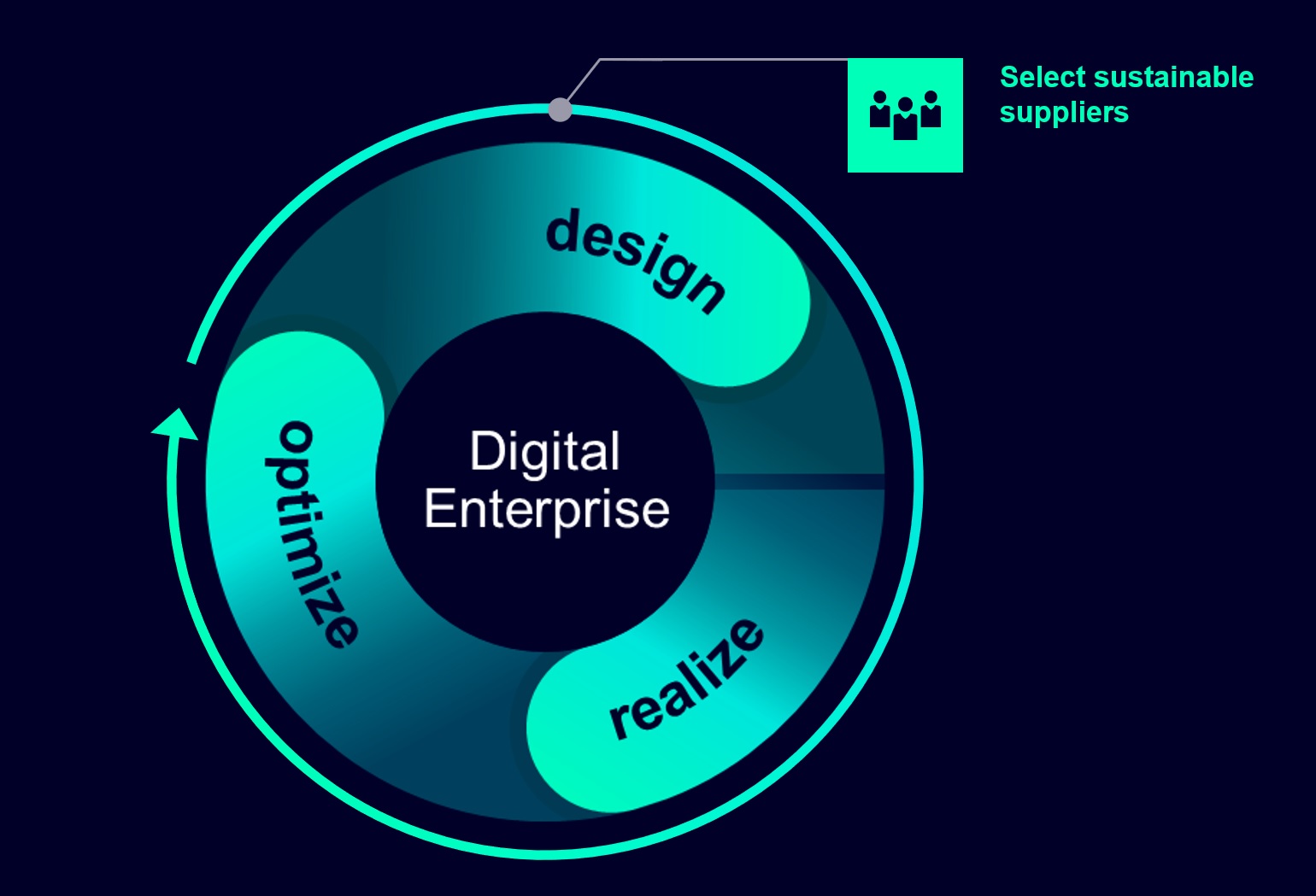

The Role of Industry 4.0 in Sustainable Manufacturing

With the advent of Industry 4.0, manufacturing is becoming smarter, more efficient, and more sustainable. Industry 4.0 encompasses a suite of technologies—such as Internet of Things (IoT), artificial intelligence (AI), machine learning (ML), and automation—that enable real-time monitoring, optimization, and predictive maintenance.

1. Smart Factories and Automation

In a smart factory, sensors and AI-powered systems gather data to monitor production in real-time, making it possible to detect inefficiencies and waste almost immediately. Automation, driven by robotics, can significantly reduce human error, improve precision, and minimize material waste. For instance, advanced robotics in car manufacturing allow for more accurate assembly with minimal excess materials.

2. Predictive Maintenance

AI-powered systems can predict when machines are likely to fail, allowing for timely maintenance and reducing unplanned downtime. This helps extend the lifespan of equipment, reduces the need for spare parts, and conserves resources. Predictive maintenance is crucial in a world where resource efficiency is paramount.

3. Data-Driven Decision Making

The data collected from various sensors and smart devices can be analyzed to optimize supply chains and manufacturing processes. By predicting demand, adjusting production schedules, and minimizing waste, AI can help manufacturers reduce their environmental footprint while improving efficiency.

Renewable Energy and Manufacturing

One of the most direct ways to make manufacturing more sustainable is by powering factories with renewable energy. As global efforts to combat climate change intensify, many manufacturing giants are turning to clean energy sources.

1. Solar and Wind Energy

Manufacturers are increasingly investing in solar and wind energy to power their factories. Siemens, for example, has been integrating wind turbines into its manufacturing processes, significantly reducing its reliance on nonrenewable sources. Similarly, General Motors has committed to running its global manufacturing plants on 100% renewable energy by 2040.

2. Decentralized Energy Systems

In some regions, decentralized energy grids powered by renewable sources are gaining traction. This allows manufacturers to become less dependent on national power grids and rely on local, renewable energy sources, reducing transmission losses and overall emissions.

Sustainable Materials and Eco-friendly Supply Chains

Sustainability is not just about how we produce, but also what we produce with. To this end, sustainable raw materials, like biodegradable plastics, recycled metals, and plant-based fibers, are becoming increasingly popular in manufacturing.

1. Eco-friendly Supply Chains

A growing number of companies are emphasizing sustainable supply chain practices. This includes sourcing raw materials from sustainable farms, working with suppliers who adopt green practices, and reducing emissions during transportation.

2. Certifications and Standards

Manufacturers are increasingly seeking certifications like ISO 14001 (environmental management) and LEED (Leadership in Energy and Environmental Design) to ensure their operations meet certain environmental standards. These certifications not only enhance the company’s reputation but also provide measurable results in terms of resource conservation.

Challenges to Achieving a Fully Green Manufacturing Future

While the advancements are promising, the road to truly green manufacturing is still fraught with challenges.

1. Financial Barriers

One of the primary challenges is the upfront cost of adopting green technologies. While energy-efficient machinery and renewable energy systems can save money in the long run, the initial investment can be significant, especially for small to medium-sized enterprises (SMEs).

2. Technological Limitations

Not all green technologies are universally applicable. For example, while 3D printing can reduce waste, it is not feasible for mass production of certain goods. Similarly, renewable energy infrastructure may not be available or cost-effective in all regions.

3. Regulatory Hurdles

Different countries have different regulations, and achieving a global standard for green manufacturing is challenging. While some governments provide incentives for sustainable practices, others may not have the regulatory frameworks in place to support them.

Case Studies of Green Manufacturing in Action

While challenges exist, several companies are proving that green manufacturing is not just a pipe dream.

- Patagonia, an outdoor apparel brand, is a leader in sustainable manufacturing, using recycled fabrics and eco-friendly dyes.

- Unilever has committed to reducing its carbon footprint by half by 2030 and is integrating sustainable practices into every step of its supply chain.

- BMW has been using recycled aluminum in its vehicles, reducing emissions from the production process.

The Road Ahead: What Needs to Happen for Manufacturing to Truly Go Green?

For manufacturing to be truly green, several things need to occur:

- Policy Support: Governments must enact policies that incentivize green technologies and penalize polluting practices.

- Industry Collaboration: Manufacturers must work together to share best practices, pool resources, and create industry-wide standards.

- Consumer Demand: As consumers increasingly demand eco-friendly products, manufacturers will have to evolve or risk obsolescence.

Conclusion

Is the future of manufacturing truly green? While significant progress is being made, we are still on the journey. Technologies like AI, renewable energy, and sustainable materials are transforming the sector, but the transition is not without its challenges. Ultimately, the path to green manufacturing will require collaboration, investment, and a shift in mindset—not just from companies, but from governments and consumers alike.