Introduction: The Future of Manufacturing is Here

In the rapidly evolving world of manufacturing, Artificial Intelligence (AI) and Human-Machine Collaboration (HMC) are becoming transformative forces. From increasing production efficiency to optimizing quality control, AI-driven systems paired with human expertise are creating a new paradigm for industries globally. As manufacturing becomes increasingly complex and competitive, AI offers the precision, consistency, and scalability that human workers alone cannot achieve. However, when combined with human intuition, creativity, and problem-solving abilities, the synergy between human and machine has the potential to revolutionize how products are designed, produced, and delivered.

In this article, we will explore what happens when AI meets human-machine collaboration in manufacturing, examining how AI augments human capabilities, the benefits and challenges of this collaboration, and the profound impact it has on the industry.

AI in Manufacturing: A Powerful Force

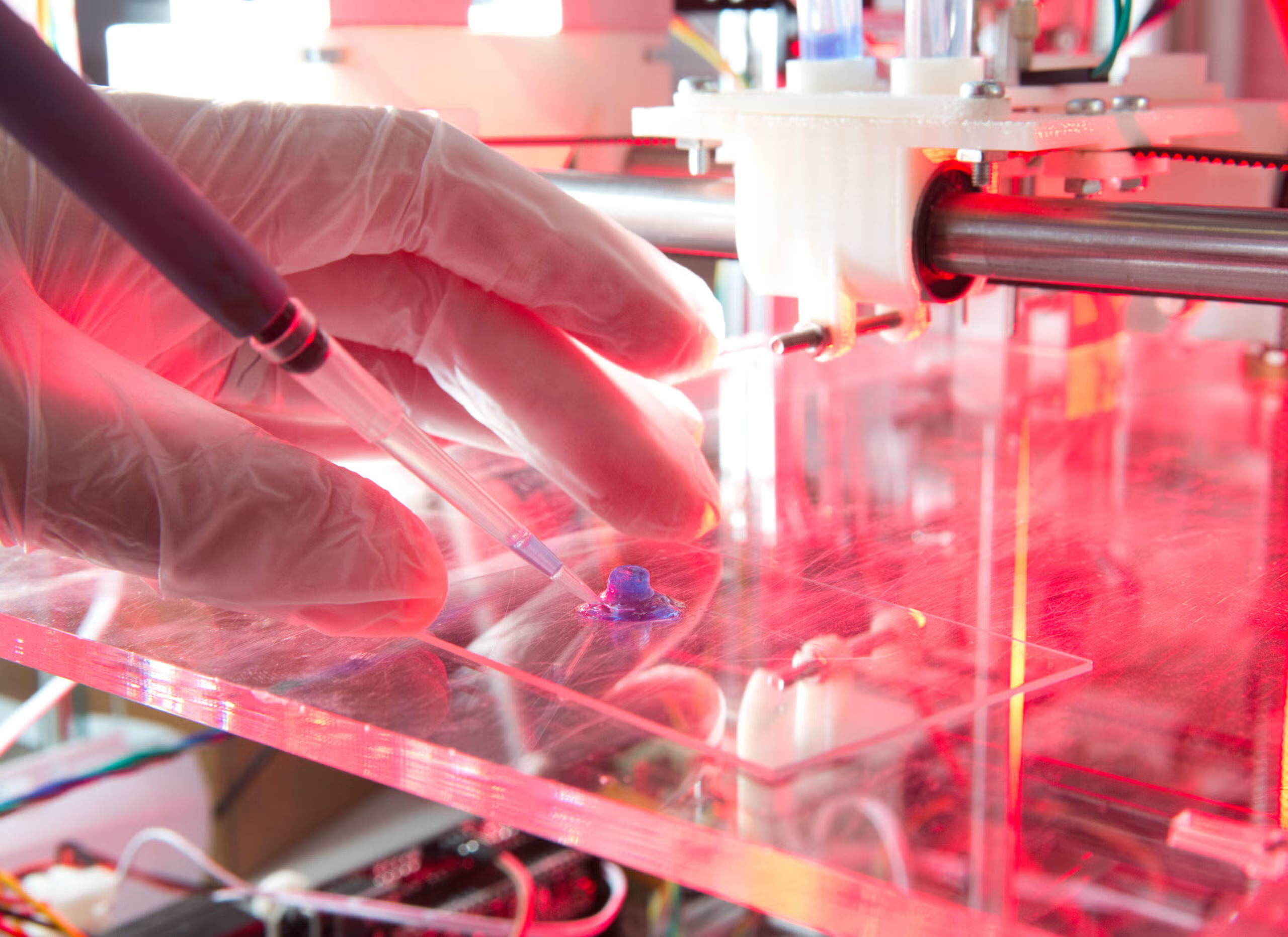

AI is already making its mark in the manufacturing sector. From predictive maintenance to automated assembly lines, AI-driven solutions are helping manufacturers streamline operations. Machine learning algorithms are now used to predict equipment failures, reducing downtime and preventing costly repairs. Robotics, coupled with AI, are reshaping assembly lines by executing complex tasks with speed and precision.

The most common AI applications in manufacturing include:

- Predictive Maintenance: By analyzing sensor data from machinery, AI can predict potential failures before they occur, preventing unplanned downtime and enhancing overall equipment efficiency (OEE).

- Quality Control: AI-driven visual inspection systems can detect defects in products at a much higher speed and accuracy than human inspectors, ensuring better product quality.

- Supply Chain Optimization: AI can predict demand trends, optimize inventory levels, and streamline logistics operations, reducing waste and improving delivery times.

- Robotics and Automation: AI-powered robots are increasingly being deployed in manufacturing to handle repetitive tasks like assembly, welding, or painting. These robots can work 24/7 without fatigue, increasing productivity.

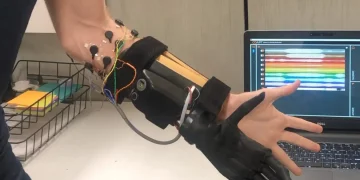

The Role of Human-Machine Collaboration

While AI can handle data-heavy tasks and execute repetitive functions with precision, it lacks the creative problem-solving skills, emotional intelligence, and nuanced decision-making abilities that humans bring to the table. This is where human-machine collaboration comes in—combining the strengths of AI and human workers to create a symbiotic relationship that enhances manufacturing capabilities.

1. Enhanced Productivity and Efficiency

The combination of AI’s precision with human adaptability results in significant productivity gains. AI can handle repetitive, mundane tasks, freeing up human workers to focus on more complex and decision-heavy aspects of production. Humans can step in when a machine encounters a task it cannot handle—whether that’s adapting to a unique component design or resolving a complex issue. This collaboration leads to faster production times, fewer errors, and increased output.

2. Human Creativity and Machine Precision

AI thrives on data and logic, but it lacks the ability to think creatively or solve novel problems. Humans, on the other hand, can bring new ideas, critical thinking, and troubleshooting skills to the process. A collaborative environment allows for a feedback loop where humans provide innovative input and AI analyzes vast amounts of data to support decision-making.

For example, in product design, engineers can leverage AI’s ability to simulate various design prototypes, while using their creativity to adapt or enhance those designs based on market trends or user feedback. This fusion of creativity and precision results in products that are both functional and forward-thinking.

3. Augmenting Human Expertise

Rather than replacing human workers, AI is enhancing their abilities. For instance, in high-stakes manufacturing environments like aerospace or pharmaceuticals, AI can assist engineers by predicting the potential failure points of components based on data analysis. Workers can then use their expertise to refine designs and prevent costly mistakes. AI acts as a tool that amplifies human intelligence, making decision-making faster, more informed, and less prone to error.

4. Adaptive Learning and Continuous Improvement

AI systems are not static—they continuously learn and evolve. In a human-machine collaborative setting, workers can provide real-time feedback to AI models, which will adapt and refine its performance based on that input. For instance, AI could recommend adjustments to a machine’s settings based on historical data or the most recent production results. Workers can then evaluate these recommendations and decide whether they should be implemented, leading to a cycle of continuous improvement.

The Benefits of Human-Machine Collaboration in Manufacturing

The fusion of AI and human expertise in manufacturing offers numerous benefits that go beyond just efficiency. The following are some of the key advantages:

1. Increased Speed and Scalability

By automating repetitive tasks and integrating AI into the workflow, manufacturers can operate at much higher speeds without compromising quality. AI systems can work around the clock, while human workers can focus on tasks that require higher cognitive skills. This combination allows companies to scale operations faster and more effectively.

2. Better Quality Control

AI-powered vision systems and sensor-based technologies can detect minute imperfections that may go unnoticed by human inspectors. By catching defects early in the production process, AI ensures that only high-quality products are shipped to customers. Combined with human oversight, this approach ensures that products meet the highest standards.

3. Cost Efficiency

AI-driven processes can significantly reduce operational costs. By improving maintenance schedules, optimizing inventory levels, and automating manual processes, companies can reduce waste, prevent equipment breakdowns, and minimize labor costs. Human oversight is still essential to monitor and adjust AI-driven systems, but the overall impact is a more cost-effective production process.

4. Worker Safety

AI can help improve workplace safety by monitoring conditions and identifying potential hazards before they escalate. For example, AI systems can monitor temperature fluctuations, humidity levels, and machine malfunctions, alerting workers to safety risks. AI-driven robots can also take over dangerous tasks, reducing the likelihood of workplace injuries.

Challenges of Human-Machine Collaboration

While the potential for collaboration is vast, several challenges must be addressed to ensure its success:

1. Skill Gaps and Training Needs

As AI becomes more integrated into manufacturing, there will be an increasing demand for workers who are skilled in both traditional manufacturing processes and modern technologies. This creates a need for continuous training and upskilling, as workers must adapt to an environment that involves working alongside intelligent machines. The ability to understand and manage AI systems will become a valuable asset in the workforce.

2. Resistance to Change

One of the primary obstacles to adopting AI in manufacturing is the resistance to change. Many workers fear that automation will lead to job loss. However, the reality is that AI is designed to augment, not replace, human capabilities. Overcoming this fear requires effective communication, transparent leadership, and providing opportunities for workers to upskill.

3. Ethical and Security Concerns

As AI plays a more prominent role in manufacturing, ethical concerns and security issues arise. Data privacy, algorithm bias, and the potential for job displacement are just a few examples. Manufacturers need to be proactive in addressing these concerns, implementing ethical AI practices, and ensuring the safety and security of the systems in place.

The Road Ahead: A Collaborative Future

Looking forward, the integration of AI in manufacturing is not just about automation—it’s about creating a collaborative ecosystem where humans and machines work together to push the boundaries of what’s possible. The future of manufacturing will be defined by the seamless interaction between human ingenuity and machine efficiency.

Smart Factories and the Internet of Things (IoT)

The next step in human-machine collaboration is the development of “smart factories,” where AI, IoT devices, and cloud computing will work together in real time. These factories will be able to self-optimize and adjust production schedules based on real-time data. For example, if an AI system detects a slowdown in one part of the production line, it can autonomously adjust other processes to maintain overall efficiency. Workers will be needed to supervise and intervene when necessary, but the majority of operations will run autonomously, increasing speed, reducing errors, and improving flexibility.

The Role of Human Creativity and Innovation

Even as AI continues to advance, human creativity and innovation will remain essential in shaping the future of manufacturing. AI can help identify patterns and optimize processes, but only humans can bring the innovative ideas and breakthroughs that truly transform industries. The key is to create an environment where AI and human workers can collaborate and learn from each other, fostering innovation and ensuring sustainable growth.

Conclusion: Embracing the Future of Manufacturing

When AI meets human-machine collaboration, the result is a manufacturing ecosystem that is more efficient, productive, and adaptable than ever before. By embracing the strengths of both human workers and AI systems, manufacturers can navigate the complexities of the modern industrial landscape, improve quality, and drive innovation.

As AI technology continues to evolve, so too will the opportunities for collaboration between humans and machines. The future of manufacturing lies in leveraging the full potential of both—combining human creativity and problem-solving skills with AI’s data-driven insights and precision. With the right approach, this collaboration will pave the way for a smarter, safer, and more sustainable manufacturing environment.