Introduction

In the face of a rapidly changing climate, resource depletion, and increasing environmental concerns, the traditional linear economic model is facing unprecedented scrutiny. This model, characterized by the familiar “take, make, dispose” pattern, has worked for decades in manufacturing, but its long-term sustainability is now under question. Enter the circular economy (CE)—a system designed to minimize waste and make the most of available resources. Unlike the linear model, which typically follows a one-way flow of materials, the circular economy promotes a restorative approach that reimagines the lifecycle of products.

The question arises: Can the circular economy truly replace the linear model in manufacturing? This article explores the fundamental differences between the two models, the potential for CE to reshape manufacturing practices, and the challenges and opportunities this transition presents.

The Linear Model: A Brief Overview

The linear economic model has dominated the industrial world for over a century. It relies on a simple process:

- Take: Extract raw materials from the Earth.

- Make: Manufacture products using these materials.

- Dispose: After use, products are discarded as waste.

This process, while efficient in terms of production and consumption, has significant drawbacks. First, it places immense pressure on finite resources, leading to their depletion. Second, it generates large quantities of waste, much of which ends up in landfills or pollutes the environment. Finally, this model encourages a culture of planned obsolescence, where products are designed for short lifecycles, incentivizing constant consumption and disposal.

For decades, the linear model has been the backbone of global manufacturing. However, as environmental concerns intensify, there is growing recognition that this model is unsustainable in the long term.

The Circular Economy: An Introduction

The circular economy, in contrast, envisions a system where waste is minimized, products are designed for reuse, and materials are continually cycled through the production process. The key principles of the circular economy include:

- Design for longevity: Products are designed to last longer, be easily repaired, and be upgradable.

- Reuse and Remanufacturing: Instead of discarding used products, manufacturers are encouraged to take them back for refurbishing, remanufacturing, or repurposing.

- Recycling: Materials from old products are recycled and incorporated into new ones, reducing the need for virgin resources.

- Business Model Innovation: Companies shift from selling products to offering services such as leasing, sharing, or subscription models, thus ensuring products remain in use for longer periods.

The circular economy seeks to close the loop on resource use and waste generation, promoting a regenerative system that benefits both businesses and the environment. But can this model truly replace the traditional linear approach in the manufacturing industry?

Key Differences Between the Linear and Circular Models

1. Resource Utilization

- Linear Model: Resources are extracted, used, and then discarded. This leads to resource depletion and pollution.

- Circular Model: Resources are kept in use for as long as possible through reusing, recycling, and remanufacturing. This minimizes waste and reduces the need for raw materials.

2. Waste Generation

- Linear Model: Waste is an inevitable byproduct of production and consumption, often ending up in landfills or incinerators.

- Circular Model: Waste is minimized or eliminated. Products are designed with the end of life in mind, promoting reuse or recycling rather than disposal.

3. Product Lifecycle

- Linear Model: Products have a relatively short lifecycle, with obsolescence built into the design.

- Circular Model: Products are designed for durability, adaptability, and recyclability, extending their lifecycle and reducing the frequency of new product creation.

4. Economic Growth

- Linear Model: Economic growth is driven by consumption and production. The more products are made and consumed, the better the economy performs.

- Circular Model: Economic growth is decoupled from resource consumption. The focus shifts from mass production to maintaining the value of products and materials through multiple cycles.

Can Circular Economy Replace Linear Manufacturing?

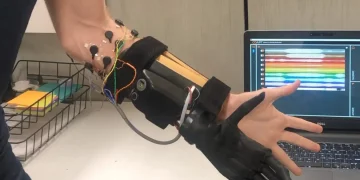

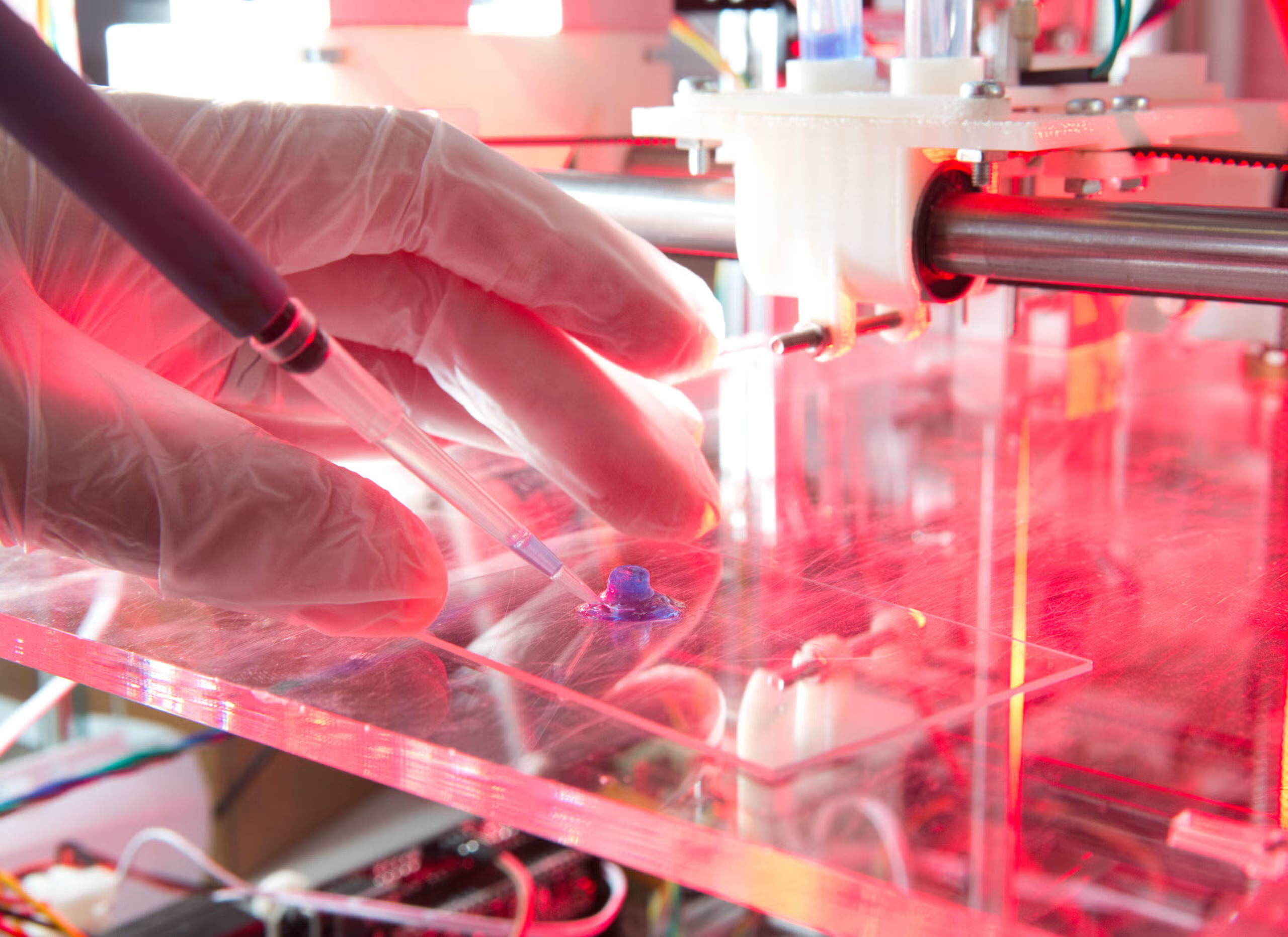

1. Technological Advancements in Manufacturing

One of the key drivers of the circular economy’s potential to replace the linear model is the advancement in manufacturing technologies. Additive manufacturing (3D printing), for instance, has revolutionized how products are made, enabling precise control over material usage and the potential for local, on-demand production. This reduces waste and the need for large-scale resource extraction.

Additionally, robotics and AI-driven optimization are making it easier to design products for disassembly, repair, or remanufacturing. By using advanced software, manufacturers can create products that are easier to recycle or repurpose. The development of smart materials that can be reclaimed and reused in new products further supports the transition toward a circular manufacturing process.

2. Business Model Shifts

To replace the linear model, businesses must evolve their traditional sales and ownership models. The circular economy encourages service-based business models, such as leasing or product-as-a-service, where products are owned by the manufacturer and leased to consumers. This ensures that products remain within the company’s control, allowing for maintenance, repair, and eventual reuse.

For example, Philips has adopted a circular model by offering “lighting as a service,” where they retain ownership of the lighting infrastructure and are responsible for its upkeep and eventual recycling. Similarly, companies like Patagonia have implemented take-back programs, where consumers can return used items for repair or recycling.

3. Consumer Behavior and Awareness

For the circular economy to thrive, consumer behavior must also shift. Historically, consumers have been accustomed to cheap, disposable products that are easy to replace. However, as environmental awareness grows, more consumers are seeking sustainable, durable, and ethically produced goods. Brands that prioritize sustainability can create a competitive advantage, appealing to environmentally conscious consumers.

The success of the circular economy depends heavily on consumer participation in recycling, repair, and reuse. Education and awareness campaigns will play a crucial role in encouraging individuals to embrace circular practices, such as returning products for recycling or choosing repairable goods over disposable ones.

4. Supply Chain Considerations

Transitioning to a circular economy also requires significant changes to global supply chains. Manufacturers must establish reverse logistics systems to collect used products, materials, or components for refurbishment or recycling. This adds complexity to operations but also presents opportunities for collaborative supply chains where companies share resources, materials, and facilities for greater efficiency.

The Internet of Things (IoT) can assist in tracking materials and products through their entire lifecycle, ensuring that they are returned and properly recycled. By creating closed-loop systems within the supply chain, manufacturers can significantly reduce their reliance on virgin resources.

5. Regulatory and Policy Support

Governments have a crucial role to play in supporting the transition from a linear to a circular economy. Policies that incentivize sustainable production practices, such as tax breaks for companies that implement circular strategies or penalties for excessive waste, can encourage widespread adoption of circular principles.

The European Union, for example, has set ambitious goals to become climate neutral by 2050 and has introduced regulations like the Circular Economy Action Plan, which aims to boost recycling, reduce waste, and ensure that resources are used more efficiently across industries. Such policies provide a roadmap for manufacturers to align their strategies with circular principles.

Challenges in Transitioning to a Circular Economy

1. Initial Investment Costs

The shift from a linear to a circular economy requires substantial upfront investment in new technologies, infrastructure, and supply chain adjustments. For small and medium-sized enterprises (SMEs), the financial burden can be a significant barrier.

However, over time, these investments can lead to cost savings through increased efficiency, reduced waste disposal costs, and the potential for new revenue streams (e.g., through product leasing or resale).

2. Technical and Logistical Barriers

Not all products are easily recyclable, and not all materials can be reused in their original form. The complexity of designing products for disassembly or remanufacturing can be challenging, especially when dealing with materials that are not yet optimized for circular processes.

Logistics is another hurdle. Developing efficient reverse logistics systems to collect and transport used products or materials for recycling can be costly and complex, especially in global supply chains.

3. Cultural Resistance

Many industries are entrenched in the linear model, and there may be cultural resistance to change. Stakeholders who benefit from the status quo may be reluctant to adopt new, unproven methods, especially if the economic benefits are not immediately apparent.

4. Consumer Participation

Even with the best intentions, the success of a circular economy depends on active consumer participation. People must be willing to return products for recycling or repair, pay higher prices for sustainable products, and change their consumption habits. Overcoming consumer convenience bias—where cheap, single-use products are often seen as the easier option—will be key.

Conclusion

The circular economy offers a compelling alternative to the traditional linear model of manufacturing, with the potential to drive both environmental sustainability and economic growth. By designing products with longer lifecycles, minimizing waste, and encouraging resource reuse, the circular economy could fundamentally reshape the way industries operate.

However, the transition is not without its challenges. The shift requires significant investment in technology, changes in business models, and collaboration across global supply chains. Moreover, policy support and consumer behavior must evolve in tandem to support the adoption of circular principles.

While the circular economy may not completely replace the linear model in the near future, it offers a sustainable path forward that could help mitigate the environmental impacts of manufacturing. With continued innovation, collaboration, and awareness, the circular economy has the potential to become the dominant model in the coming decades.