Introduction: The Shift Toward Sustainability

In the face of climate change and growing environmental concerns, the future of manufacturing is undergoing a profound transformation. Traditionally, manufacturing has been associated with pollution, resource depletion, and high carbon emissions. However, the rapid development of green technologies—innovations designed to minimize environmental impact—has spurred a new wave of industrial change. These technologies promise not only to enhance energy efficiency but also to revolutionize production processes and the very way industries operate.

But the question remains: Will green technologies ultimately replace traditional manufacturing methods, or will both coexist in the future?

Understanding Green Technologies in Manufacturing

At the core of this debate is the definition of “green technologies.” These are innovations that aim to reduce environmental impact, conserve resources, and improve energy efficiency. In the manufacturing industry, green technologies can include everything from renewable energy sources and electric-powered machinery to innovative materials and waste-reduction strategies.

Some key green technologies making waves in manufacturing include:

- Renewable Energy Integration: Solar, wind, and hydro power are replacing fossil fuels in the production process, reducing reliance on carbon-heavy energy sources.

- 3D Printing (Additive Manufacturing): This process reduces waste by creating products layer by layer, eliminating the need for excessive raw materials.

- Circular Economy Practices: Rather than relying on the traditional “take-make-dispose” model, industries are now focusing on “reduce, reuse, recycle,” aiming to create closed-loop systems for materials.

- Green Chemistry: The use of environmentally friendly chemicals to replace hazardous substances in manufacturing processes.

- Smart Factories and IoT: Automation and the Internet of Things (IoT) allow for optimized production with minimal waste, real-time monitoring, and energy efficiency.

These green technologies hold significant potential to reshape the landscape of manufacturing, making it cleaner, smarter, and more sustainable.

Traditional Manufacturing: A Legacy of Pollution and Resource Depletion

For centuries, traditional manufacturing processes have been built on a foundation of mass production and resource extraction. Factories churned out goods using fossil fuels, synthetic materials, and processes that resulted in high levels of pollution and environmental degradation. Key characteristics of traditional manufacturing include:

- High Energy Consumption: Factories typically rely on non-renewable energy sources like coal, oil, and natural gas to power machinery.

- Waste Generation: Traditional processes often produce large amounts of waste, which either ends up in landfills or contributes to environmental contamination.

- Pollution: Emissions from factories release harmful gases like CO2, methane, and particulate matter, contributing to global warming and air pollution.

- Resource Depletion: Extracting and using raw materials such as metals, plastics, and textiles leads to the depletion of natural resources.

While traditional manufacturing is incredibly effective at meeting demand for goods on a large scale, it is increasingly being criticized for its unsustainable practices. This has led industries to consider alternative, more environmentally friendly methods.

The Promise of Green Technologies

The rise of green technologies in manufacturing offers a promising path toward sustainability. Let’s take a closer look at how these technologies could potentially replace or enhance traditional manufacturing.

1. Energy Efficiency and Renewable Energy

One of the most significant changes that green technologies can bring to manufacturing is the integration of renewable energy sources. Solar panels, wind turbines, and hydropower are increasingly being used to power factories and production facilities, reducing the reliance on fossil fuels. For example, companies like Tesla and IKEA have invested heavily in renewable energy projects to power their manufacturing processes.

In the future, we can expect a shift towards energy-efficient machinery and production systems that run on green energy, reducing emissions and lowering operating costs in the long term.

2. 3D Printing and Additive Manufacturing

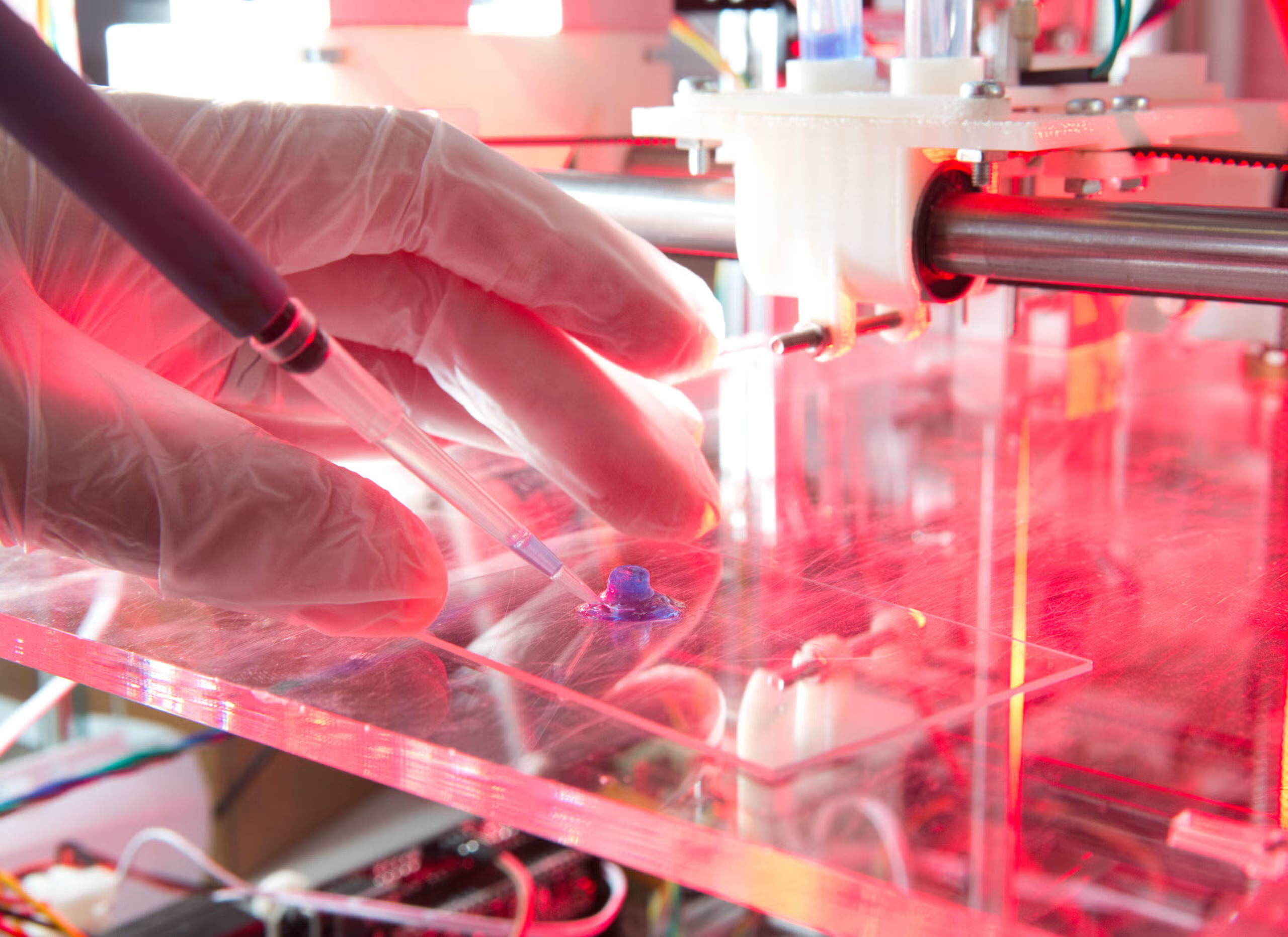

Traditional manufacturing methods often involve cutting, casting, or molding materials, which generates significant waste. 3D printing, on the other hand, creates products layer by layer, using only the materials required for the design. This results in minimal waste and greater precision.

Additive manufacturing also opens up new opportunities for on-demand production, meaning goods can be produced only when they are needed, further reducing waste and overproduction. Industries ranging from aerospace to fashion are already using 3D printing to create prototypes, parts, and even end-user products.

3. Circular Economy and Waste Reduction

In traditional manufacturing, products are often designed for obsolescence—once they reach the end of their useful life, they are discarded, creating enormous amounts of waste. The circular economy flips this model on its head by promoting the reuse, recycling, and repurposing of materials.

For instance, some companies are using recycled materials in their production processes, while others are designing products that can be easily disassembled for recycling. The goal is to create a closed-loop system where the life cycle of materials is extended, reducing waste and conserving resources.

4. Green Chemistry and Sustainable Materials

A significant portion of traditional manufacturing relies on hazardous chemicals and non-sustainable materials, which contribute to pollution and environmental harm. Green chemistry offers solutions to this problem by developing chemical processes that are less toxic, more efficient, and more environmentally friendly.

Innovations in materials science also allow for the development of sustainable alternatives to common raw materials. For example, bioplastics made from plant-based materials are starting to replace petroleum-based plastics in packaging and product manufacturing.

5. Smart Manufacturing and IoT

The rise of smart factories powered by the Internet of Things (IoT) is another exciting development. IoT-enabled devices can monitor energy consumption, optimize production schedules, and predict maintenance needs, leading to more efficient use of resources. This means less waste, fewer disruptions, and a more streamlined production process overall.

Smart manufacturing systems also enable real-time data analysis, allowing manufacturers to identify inefficiencies and reduce their environmental footprint.

Challenges to Widespread Adoption of Green Technologies

While green technologies hold immense potential, several challenges must be overcome for them to fully replace traditional manufacturing methods.

1. High Initial Investment

Many green technologies, particularly renewable energy systems and advanced manufacturing equipment, require significant upfront investment. For small and medium-sized enterprises (SMEs), these costs can be prohibitive.

2. Transitioning Existing Infrastructure

Most manufacturers have existing infrastructure optimized for traditional production methods. Transitioning to green technologies may require costly retrofitting or even the construction of entirely new facilities. This can be a deterrent for companies that are reluctant to disrupt their established operations.

3. Regulatory and Policy Barriers

In some regions, regulatory frameworks and policies still favor traditional manufacturing methods. Governments may need to introduce incentives, subsidies, or tax breaks to make green technologies more attractive to manufacturers.

4. Technological Maturity

While green technologies are advancing rapidly, some are still in the early stages of development or may not yet be scalable to industrial levels. For example, widespread adoption of 3D printing in large-scale manufacturing is still limited by factors like speed, material options, and cost.

5. Supply Chain Challenges

Green technologies often rely on a new set of raw materials or processes that might not yet be widely available. Establishing a sustainable supply chain for these materials can be complex and costly.

Coexistence or Replacement?

While green technologies offer significant benefits, it is unlikely that they will completely replace traditional manufacturing in the near future. Rather, we may see a hybrid model emerge, where both green and traditional methods coexist, each serving different needs in the global economy.

For example, green technologies may dominate sectors where environmental impact is a critical concern—such as renewable energy, electric vehicles, and sustainable fashion—while traditional methods may remain relevant in industries that require mass production and cannot yet benefit from green alternatives.

Ultimately, the future of manufacturing will likely involve a combination of sustainable innovation and established practices, leading to a more balanced and environmentally responsible approach to industrial production.

Conclusion: A Greener Future Ahead

As the world continues to grapple with the realities of climate change, the shift towards green technologies in manufacturing is no longer just a possibility—it is an inevitability. From renewable energy sources and 3D printing to smart factories and circular economy practices, these innovations offer a path toward cleaner, more sustainable production.

While challenges remain, the potential for green technologies to reshape the manufacturing landscape is immense. In the years to come, we are likely to see a gradual but steady transition towards greener, more efficient, and more sustainable manufacturing practices. Whether green technologies will entirely replace traditional manufacturing remains to be seen, but one thing is clear: the future of manufacturing is green.