Industry 4.0, often referred to as the Fourth Industrial Revolution, is a term that has captivated the imagination of business leaders, policymakers, and technologists alike. It represents the ongoing transformation of industries, driven by the integration of cutting-edge technologies like artificial intelligence (AI), the Internet of Things (IoT), big data analytics, robotics, and advanced manufacturing techniques. Some argue that we are at the cusp of a groundbreaking revolution, while others believe the concept is more hype than reality. So, is Industry 4.0 overhyped, or is it truly just getting started?

This article explores both sides of the debate, analyzing the potential, progress, and challenges of Industry 4.0. Let’s dive deep into what Industry 4.0 really means, how it’s shaping the future, and whether we are only beginning to scratch the surface.

What is Industry 4.0?

Before we dive into the debate, let’s define what Industry 4.0 encompasses. Industry 4.0 refers to the next phase of industrialization, characterized by the fusion of digital, physical, and biological systems. It builds on the foundation of previous industrial revolutions, where mechanization, mass production, and automation redefined industries globally.

The core elements of Industry 4.0 include:

- IoT (Internet of Things): Connecting devices, machines, and systems to the internet, enabling real-time data collection and analysis.

- Artificial Intelligence and Machine Learning: Systems that can learn from data and make decisions autonomously or semi-autonomously.

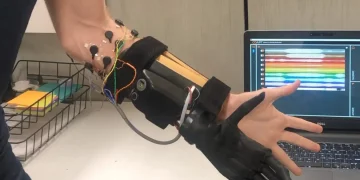

- Automation and Robotics: The use of robots and automated systems to perform repetitive, dangerous, or complex tasks.

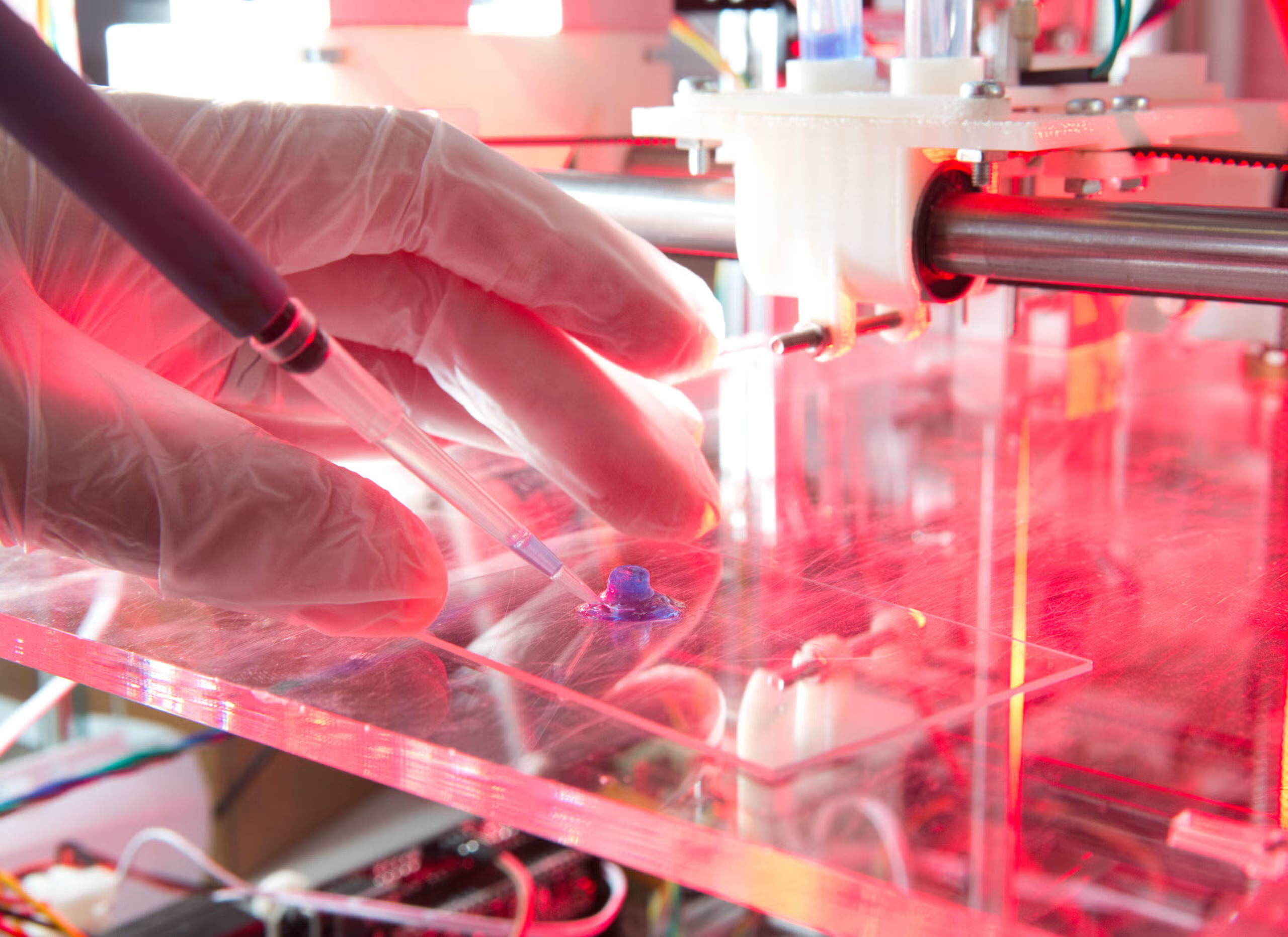

- Advanced Manufacturing Technologies: Technologies like 3D printing, smart sensors, and augmented reality (AR) that enhance production processes.

- Big Data Analytics: The ability to analyze large volumes of data from various sources to derive insights and optimize processes.

Together, these technologies create a smart, interconnected environment where everything from supply chains to production lines is more efficient, adaptive, and responsive.

The Overhyped Side: The Reality Check

While the promises of Industry 4.0 are undeniably enticing, there are a few compelling arguments that suggest the hype may have outpaced the actual adoption and impact of these technologies.

1. Slow Adoption and High Costs

One of the biggest barriers to the full realization of Industry 4.0 is the slow pace of adoption. Many industries, especially in manufacturing, are still reliant on legacy systems, and transitioning to Industry 4.0 technologies requires significant investment in both time and money. For many companies, the cost of retrofitting old systems with new technology can be prohibitive, especially when the ROI is uncertain.

According to a 2020 McKinsey report, only about 10% of companies in the manufacturing sector are fully utilizing Industry 4.0 technologies. For most, the transition to Industry 4.0 remains a slow, incremental process, hindered by the high initial cost of new infrastructure, training, and integration challenges.

2. Technological Fragmentation

While we hear a lot about the potential of smart factories, connected supply chains, and autonomous robots, the reality is that the integration of these technologies is often fragmented and siloed. Different machines, devices, and systems often operate on different standards, creating interoperability issues.

The promise of seamless communication between machines, suppliers, and manufacturers is difficult to realize when technologies are still in early stages of development. Companies often face challenges in integrating new technologies with existing systems or in ensuring that all devices on the factory floor can “talk” to one another. Without standardized protocols and a unified platform, the vision of a fully connected ecosystem remains elusive for many.

3. Cybersecurity Risks

Another critical concern is cybersecurity. As more devices become interconnected, the risk of cyber-attacks grows. IoT devices, for example, can be vulnerable to hacking, and industrial control systems (ICS) are often targeted by malicious actors looking to disrupt operations.

In 2017, the NotPetya cyber-attack paralyzed companies worldwide, including some in the manufacturing sector. The threat of cyber-attacks is particularly high in industries with older systems that may not have robust cybersecurity measures in place. As Industry 4.0 continues to expand, these vulnerabilities will need to be addressed in real time, but many organizations are still lagging behind in implementing comprehensive cybersecurity frameworks.

4. The Skills Gap

Industry 4.0 requires a new set of skills. The technologies involved—AI, robotics, big data—demand expertise that is not readily available in the current workforce. Many workers in manufacturing are not equipped with the skills needed to operate and maintain advanced systems. Retraining employees and ensuring they have the necessary digital literacy can be a time-consuming and expensive process.

In fact, the World Economic Forum estimates that by 2025, over 85 million jobs could be displaced by automation, while 97 million new roles will emerge. However, these new roles will require a level of technical expertise that may not yet exist at scale. As a result, industries may struggle to find talent to manage the new technologies or may face a prolonged transition period as the workforce catches up.

The “Just Getting Started” Side: The Path Forward

Despite the challenges, it would be premature to dismiss Industry 4.0 as mere hype. Many advancements are being made, and the potential benefits are enormous. Let’s take a look at why Industry 4.0 is likely just getting started.

1. Continuous Innovation

The technologies that power Industry 4.0 are evolving at an exponential rate. For instance, AI and machine learning algorithms are becoming more sophisticated, enabling predictive maintenance, improved supply chain logistics, and even autonomous decision-making. Robotics, once limited to repetitive tasks, is now able to perform complex actions with high precision.

The adoption of 5G technology will further enhance the ability to connect devices in real time with lower latency, paving the way for more seamless operations. The rise of quantum computing could also open up new possibilities for industrial processes, allowing for faster and more accurate simulations of manufacturing environments.

As these technologies mature, their cost will decrease, making them more accessible to a broader range of businesses. In the coming years, we’re likely to see widespread adoption of Industry 4.0 technologies across industries that haven’t yet fully embraced them.

2. Increased Efficiency and Productivity

One of the most tangible benefits of Industry 4.0 is the significant increase in efficiency and productivity it can bring. IoT sensors, for example, can provide real-time data on the performance of equipment, allowing companies to identify bottlenecks and inefficiencies before they become major problems. AI-powered analytics can forecast demand more accurately, optimizing supply chain operations.

Companies that have embraced Industry 4.0 technologies have already seen impressive results. Siemens, for example, has reported a 20% increase in production efficiency through the use of AI and digital twins—virtual replicas of physical objects used to simulate and optimize processes. As more companies embrace these tools, the impact on global productivity could be profound.

3. Sustainability and Circular Economy

Another compelling reason why Industry 4.0 is only getting started is its potential to drive sustainability. Technologies like AI and big data can help companies optimize their resource usage, reducing waste and lowering energy consumption. The rise of additive manufacturing (3D printing) also enables the creation of products with minimal material waste.

In addition, Industry 4.0 technologies support the transition to a circular economy, where products are designed for reuse, refurbishment, and recycling. With greater visibility into the lifecycle of materials, companies can reduce their environmental footprint and create more sustainable business models.

4. Global Connectivity and Smart Cities

Industry 4.0 is not limited to factories and warehouses. It has the potential to redefine entire cities. Smart cities, powered by interconnected sensors, AI, and big data, can become more efficient, livable, and sustainable. From optimizing traffic flow to improving waste management and energy distribution, Industry 4.0 can transform urban environments.

Global connectivity is also playing a crucial role in the spread of Industry 4.0. With the proliferation of the internet, cloud computing, and mobile technologies, businesses across the world can tap into a global network of data and resources. This interconnectedness will create new opportunities for collaboration, innovation, and market access.

Conclusion: Overhyped or Just Getting Started?

So, is Industry 4.0 overhyped or just getting started? The truth is somewhere in between. While some of the early hype may have overstated the speed at which these technologies would be adopted, there’s no denying that we are in the early stages of a revolution that will fundamentally change the way industries operate.

The technologies that define Industry 4.0 are powerful and transformative, but the full realization of their potential will take time. Adoption is slow, and significant hurdles remain, including high costs, cybersecurity risks, and a skills gap. However, the rate of innovation is accelerating, and the potential benefits—from increased efficiency and productivity to sustainability and smarter cities—are enormous.

For businesses and governments, the key to success will be embracing these technologies thoughtfully, addressing the challenges head-on, and preparing for a future where digital, physical, and biological systems are more intertwined than ever before.