The industrial sector, historically seen as the backbone of economies, is experiencing an epochal shift. From supply chains to manufacturing processes, the infusion of Big Data into industrial operations has begun a revolution, one that promises enhanced efficiency, better decision-making, and competitive advantages for those who master its use. But can Big Data really transform the industrial sector, or is it just a buzzword? This article explores the profound impact of Big Data on industries and sheds light on how businesses can leverage this powerful tool to create smarter, more sustainable operations.

What is Big Data?

At its core, Big Data refers to vast volumes of data generated from a wide range of sources: machines, sensors, human interactions, social media, and more. It is characterized by the 3 Vs:

- Volume: The sheer amount of data produced daily is staggering.

- Velocity: The speed at which data is generated, processed, and analyzed.

- Variety: The diversity of data types, from structured data in databases to unstructured data like text, images, and sensor readings.

In the industrial sector, Big Data encompasses everything from machine performance data and sensor readings to supply chain logistics and consumer feedback. But it’s not just the raw data that matters. It’s the ability to analyze and extract actionable insights from this data that drives transformation.

The Role of Big Data in the Industrial Sector

1. Predictive Maintenance: Keeping Machines Running Smoothly

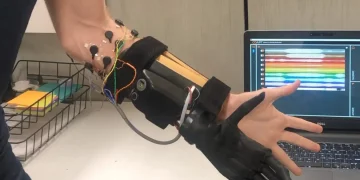

One of the most immediate and impactful uses of Big Data in the industrial world is predictive maintenance. Traditionally, factories and manufacturing plants would schedule maintenance checks for machinery at regular intervals—whether the machine needed it or not. This often led to unnecessary downtime or, worse, costly breakdowns.

With the advent of sensors and IoT (Internet of Things) devices, machines can now generate real-time data on their operational status. Big Data tools can process this data to identify patterns, detect anomalies, and predict when a machine is likely to fail. By leveraging predictive analytics, companies can perform maintenance only when needed, reducing downtime, and extending the life of expensive equipment.

Take General Electric (GE), for example. GE’s “Predix” platform uses data collected from machines across various industries to monitor and analyze performance. This allows industries like aviation and energy to predict when a part will fail and replace it before it leads to catastrophic damage. This shift from reactive to proactive maintenance is saving industries billions annually.

2. Optimizing Supply Chains: Speed and Precision in Motion

Another area where Big Data is making significant waves is in supply chain optimization. The global supply chain is a complex, interconnected system involving multiple stakeholders, transportation routes, inventory management, and demand forecasting. In the past, inefficiencies like delayed shipments or overstocking plagued industries.

By using Big Data analytics, companies can gain deep insights into their supply chains and improve operations. Real-time tracking of goods, dynamic route optimization, and demand forecasting are just a few areas where data-driven decisions can enhance supply chain efficiency.

For instance, Amazon uses Big Data to optimize its warehouse operations and delivery routes, ensuring that items are always stocked in the most efficient manner and delivered as quickly as possible. Their system can predict which products are likely to be in demand and preemptively distribute stock across their warehouses. This reduces wait times for consumers and cuts operational costs for Amazon.

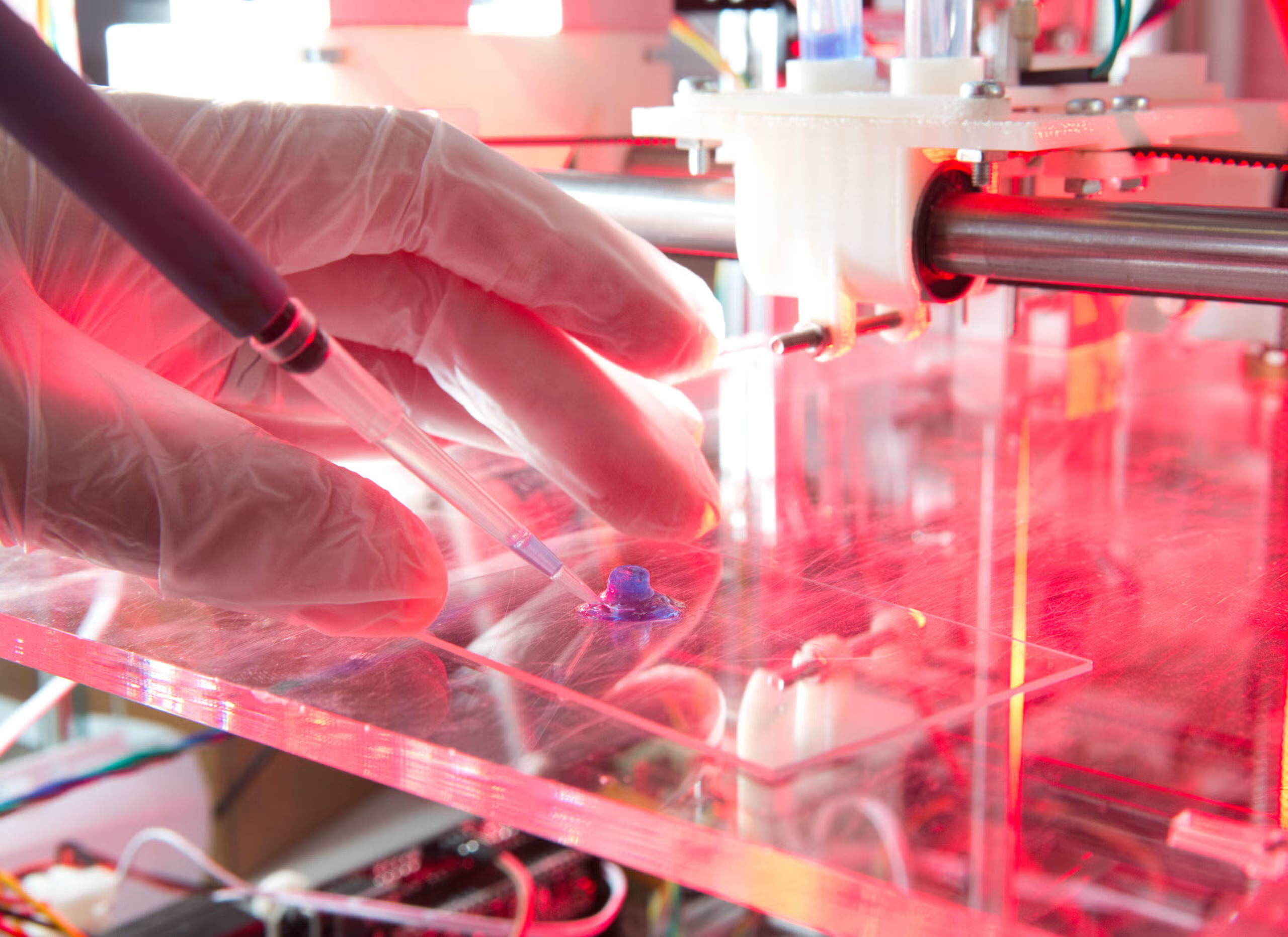

3. Enhancing Production Processes: Efficiency and Quality Control

Manufacturing processes are being transformed through the integration of Big Data. Machine learning algorithms and AI can analyze data from production lines in real-time to identify inefficiencies or quality control issues. This allows manufacturers to streamline operations, increase throughput, and minimize waste.

Siemens has been pioneering the use of Big Data in manufacturing. The company’s Digital Factory approach integrates data from all stages of production—from design and planning to manufacturing and logistics. By using advanced analytics, Siemens can offer real-time insights into production efficiency, predict demand surges, and fine-tune processes to ensure high-quality output.

4. Energy Efficiency: Powering Industrial Sustainability

The industrial sector is one of the largest consumers of energy worldwide. As companies face increasing pressure to reduce their carbon footprint and embrace sustainability, Big Data offers an invaluable tool for energy management.

By using data from smart meters, sensors, and IoT devices, companies can monitor their energy consumption in real-time and identify areas where energy is being wasted. Through predictive analytics, they can optimize energy use, ensuring that machines are only powered when needed, and excess energy consumption is reduced.

A prime example is Schneider Electric, which offers energy management solutions powered by Big Data. By analyzing energy data from industrial plants, Schneider Electric helps companies optimize their energy use, reducing costs and lowering their environmental impact. This not only saves money but aligns with global sustainability goals.

Challenges in Implementing Big Data in Industry

While Big Data promises numerous benefits, its implementation is not without challenges. For industries looking to harness its potential, several key obstacles must be overcome:

1. Data Security and Privacy Concerns

With the collection of vast amounts of data comes the need for robust security measures. Industrial data often includes sensitive information, such as intellectual property or proprietary machine performance data. Ensuring that this data is protected from cyber threats is critical.

Companies must invest in secure data storage, encryption protocols, and cybersecurity practices to safeguard their operations. The rise of cyber-physical systems in manufacturing adds another layer of complexity, as these systems integrate digital and physical components that must be protected from cyber-attacks.

2. Data Quality and Integration Issues

Industrial data comes from a wide array of sources, each with its own format and structure. The challenge is not only to collect this data but also to ensure its quality and integrate it seamlessly into existing systems. Data silos can prevent comprehensive analysis, making it difficult to uncover meaningful insights.

To address this, companies need to adopt sophisticated data management strategies that clean, standardize, and integrate data from diverse sources. This will require collaboration between data scientists, engineers, and operations teams to ensure that the right data is being analyzed at the right time.

3. Talent Gap: The Need for Data Scientists

The successful implementation of Big Data in the industrial sector requires skilled professionals who can analyze vast datasets and turn them into actionable insights. However, there is a global shortage of qualified data scientists with the expertise needed to interpret complex industrial data.

Companies must invest in training programs, partnerships with educational institutions, and collaboration with data science professionals to bridge this talent gap. Additionally, fostering a culture of data literacy across all levels of the organization can help businesses make the most of their Big Data investments.

The Future of Big Data in Industry

As technologies like AI, IoT, and blockchain continue to advance, the potential for Big Data to revolutionize the industrial sector will only grow. Companies that embrace this transformation early stand to gain significant competitive advantages.

The future of Big Data in the industrial sector will likely be shaped by several key trends:

- Artificial Intelligence and Machine Learning: These technologies will continue to improve predictive maintenance, optimize production lines, and enhance supply chain management.

- Edge Computing: With the increasing number of devices generating data, edge computing will allow data to be processed closer to its source, reducing latency and enabling faster decision-making.

- Blockchain for Transparency and Security: Blockchain technology could enhance the security and transparency of industrial data, particularly in supply chains and equipment management.

- 5G Connectivity: The rollout of 5G networks will provide faster, more reliable connections for IoT devices, allowing industries to capture and analyze data in real-time, no matter where their operations are located.

Conclusion

Big Data is no longer a futuristic concept but a present-day reality that is transforming the industrial sector. From predictive maintenance and supply chain optimization to enhanced production processes and energy efficiency, the potential benefits are immense. However, to truly unlock the power of Big Data, companies must overcome challenges like data security, integration issues, and the talent gap. The future of Big Data in industry looks promising, with AI, IoT, and other emerging technologies driving further innovations.

For those in the industrial sector, the time to embrace Big Data is now. The industries that can harness its power will not only become more efficient but will also lead the way toward a smarter, more sustainable future.