In the fast-evolving world of industrial manufacturing, 3D printing stands at the forefront, promising to revolutionize how products are conceived, designed, and produced. Also known as additive manufacturing, 3D printing refers to the process of creating three-dimensional objects from a digital file by layering material. This technology, once relegated to the realm of prototyping, has rapidly progressed to a level where it is now being used for mass production in industries ranging from aerospace to healthcare, automotive to fashion.

But is 3D printing truly the future of industrial production? In this article, we explore the opportunities, challenges, and potential of 3D printing as a transformative force in industrial production.

The Evolution of 3D Printing: From Prototype to Production

The journey of 3D printing has been nothing short of remarkable. Originally developed in the 1980s by Charles Hull, the inventor of stereolithography (SLA), 3D printing started as a tool for rapid prototyping. It allowed designers and engineers to create tangible models of their designs quickly and affordably. However, this technology has now evolved far beyond mere prototyping.

With advancements in materials, techniques, and machines, 3D printing is capable of producing high-quality, functional end-products. Today, it’s used in a wide array of industries to create everything from intricate medical implants to specialized aerospace parts, personalized consumer products, and even entire buildings.

How 3D Printing Works

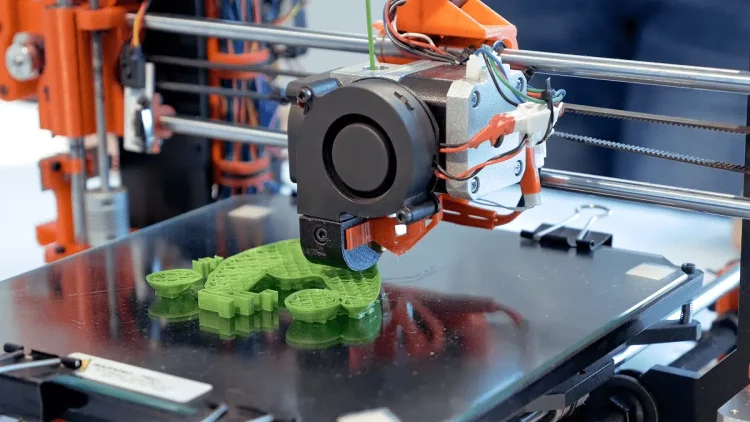

The 3D printing process begins with a digital model of the object to be produced. This model is created using Computer-Aided Design (CAD) software or 3D scanning technology. The digital design is then sliced into thin layers by slicing software, which converts the design into machine-readable instructions. The printer deposits material layer by layer, gradually building up the object.

Several methods of 3D printing exist, including:

- Fused Deposition Modeling (FDM): The most common consumer-level method, where a thermoplastic filament is heated and extruded onto the print bed layer by layer.

- Stereolithography (SLA): Uses UV light to cure liquid resin into solid layers, resulting in high-precision prints.

- Selective Laser Sintering (SLS): A laser is used to sinter powdered material, typically plastic or metal, to create strong and durable parts.

- Electron Beam Melting (EBM): Utilizes an electron beam to melt metal powder, which is then deposited layer by layer.

The choice of method depends on factors such as material requirements, precision, and the scale of production.

3D Printing in Industrial Production

1. Customization and On-Demand Production

One of the key benefits of 3D printing in industrial production is the ability to create highly customized parts on demand. Unlike traditional manufacturing methods, which rely on molds, dies, or machining to create parts, 3D printing allows for the easy alteration of designs without significant cost increases. This is especially valuable in industries such as aerospace, automotive, and healthcare, where customization is often required for individual components.

For example, companies like General Electric and Boeing use 3D printing to produce customized engine parts and components that meet exact specifications. These parts can be manufactured on-site, reducing the need for inventory and allowing for faster turnaround times.

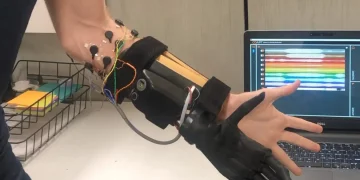

Similarly, in the healthcare sector, 3D printing is used to create personalized medical devices, implants, and even prosthetics. Custom-designed implants are tailored to fit a patient’s anatomy, leading to improved outcomes and faster recovery times. Companies such as Materialise and Stratasys have already made significant strides in this area.

2. Cost Efficiency and Waste Reduction

Traditional manufacturing processes often involve significant waste, especially when machining large metal blocks into intricate shapes. 3D printing, on the other hand, is an additive process, meaning material is deposited only where it’s needed, resulting in minimal waste. This can significantly reduce material costs and is more environmentally friendly, particularly when using sustainable or recycled materials.

Additionally, the ability to print parts on demand reduces the need for large inventories, leading to cost savings in storage and transportation. As supply chains become increasingly global, the benefits of 3D printing’s decentralized production model become even more evident.

3. Speed and Flexibility

The speed with which a 3D printer can create complex parts is another major advantage. Traditional manufacturing methods, such as injection molding, can take weeks or months to set up molds, whereas 3D printing can create a prototype or end-use part in a matter of hours or days. This drastically reduces lead times, allowing manufacturers to be more agile and responsive to market demands.

Moreover, 3D printing can facilitate iterative design, enabling rapid prototyping and quick modifications. This allows designers to test multiple iterations of a product without the long delays inherent in traditional manufacturing methods.

4. Complex Geometries and Innovation

Another remarkable benefit of 3D printing is its ability to create highly complex geometries that would be impossible or cost-prohibitive to produce using traditional manufacturing techniques. This is particularly useful in industries such as aerospace and automotive, where parts are often required to meet strict performance and weight requirements.

For instance, NASA uses 3D printing to create intricate parts for spacecraft, which can reduce both the weight and cost of components. The ability to print parts with internal structures (such as lattice designs) that are both lightweight and strong opens up new possibilities for innovation.

5. Sustainability and Green Manufacturing

As concerns about environmental sustainability continue to grow, 3D printing offers a promising solution. The additive nature of 3D printing results in less material waste compared to subtractive methods like CNC machining. In addition, 3D printing allows for the use of recycled materials or bio-based materials, reducing the environmental impact of manufacturing processes.

For example, Nike has experimented with using 3D printing to create shoes with parts that are made from recycled plastic. Similarly, companies in the construction industry are exploring 3D printing for building homes and other structures, using sustainable materials like recycled concrete.

Challenges Facing 3D Printing in Industrial Production

Despite its many advantages, 3D printing is not without its challenges, particularly in the context of industrial production.

1. Material Limitations

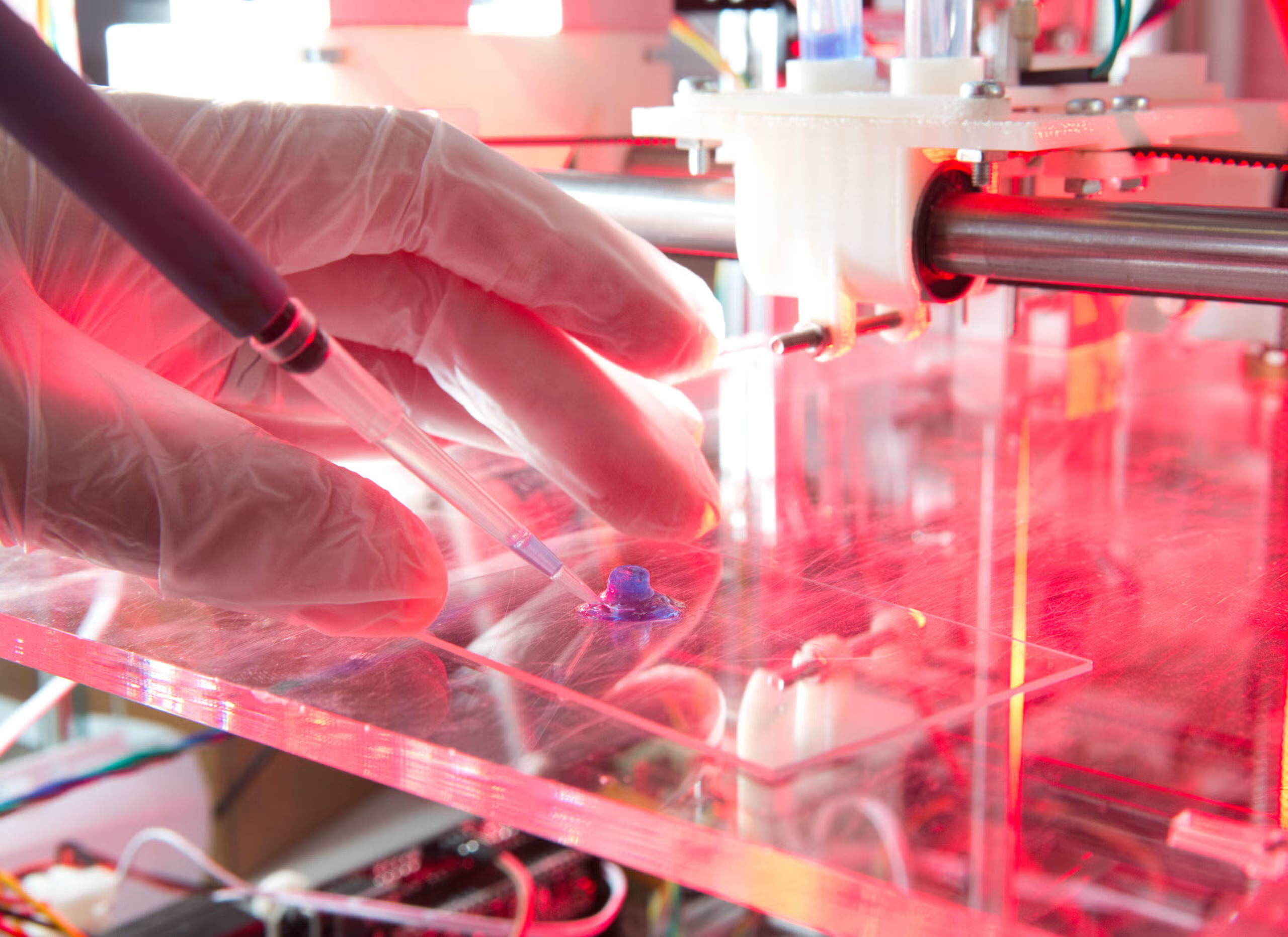

While 3D printing offers a wide variety of materials, such as plastics, metals, ceramics, and even biological materials, the range of materials suitable for high-performance applications remains limited. The material properties, such as strength, durability, and heat resistance, may not yet meet the standards required for certain industries, especially those in aerospace or heavy manufacturing.

Moreover, the cost of high-performance 3D printing materials can be prohibitively expensive, limiting their use in large-scale production.

2. Speed and Scale Limitations

While 3D printing can be fast for prototyping or producing small batches, it’s still relatively slow when compared to traditional manufacturing methods for large-scale production. For example, injection molding can produce thousands of parts in a matter of hours, while 3D printing might take days to produce a similar number of items.

For industries that require mass production, 3D printing is not yet a viable alternative at the scale of traditional methods.

3. Post-Processing and Surface Finish

3D printed parts often require additional post-processing, such as cleaning, curing, and surface finishing, to meet industry standards. This adds extra time and cost to the production process, which can make 3D printing less attractive for certain applications, especially where high-volume manufacturing is required.

4. Intellectual Property and Security

The ease of replication in 3D printing raises concerns about intellectual property (IP) rights and the potential for counterfeit parts. For industries that rely heavily on proprietary designs and technologies, such as aerospace or healthcare, ensuring the security and integrity of 3D printed parts is a critical issue. Companies must invest in security measures to protect their designs from being stolen or copied.

5. Regulatory Challenges

As 3D printing becomes more widespread in industries such as healthcare and aerospace, regulatory bodies are faced with the challenge of keeping pace with this new technology. Ensuring that 3D printed parts meet safety and quality standards is critical, and current regulations may not be equipped to handle the unique nature of 3D printed components.

The Future of 3D Printing in Industrial Production

The potential of 3D printing in industrial production is immense, but its full adoption will require overcoming the challenges outlined above. As technology continues to advance, the materials available for 3D printing will improve, offering greater strength, durability, and heat resistance. Innovations in printer speed and scalability may also make 3D printing more competitive with traditional manufacturing methods.

Moreover, as industries adopt Industry 4.0 technologies like the Internet of Things (IoT), artificial intelligence (AI), and machine learning, 3D printing will become more integrated into smart factories and production lines, further optimizing manufacturing processes.

Ultimately, while 3D printing may not fully replace traditional manufacturing in the near future, it will undoubtedly play a critical role in reshaping how we produce goods, making manufacturing more flexible, sustainable, and customized than ever before.