Industry 4.0, the fourth industrial revolution, is transforming the way we think about manufacturing and work environments. With advancements in smart technologies like the Internet of Things (IoT), Artificial Intelligence (AI), robotics, and big data analytics, Industry 4.0 promises to reshape industries, boosting efficiency, productivity, and, perhaps most importantly, worker safety. But the key question remains: Can Industry 4.0 really improve worker safety?

The integration of these advanced technologies offers exciting prospects, but it also raises concerns. Will these systems truly reduce accidents, prevent injuries, and improve the overall well-being of workers? Or will they introduce new risks and challenges? This article explores both the potential benefits and challenges of Industry 4.0 in enhancing worker safety, shedding light on its current applications and the future possibilities.

The Changing Landscape of Worker Safety

Traditional Workplace Safety: The Old Guard

For decades, workplace safety has focused on reactive measures. Organizations primarily relied on safety protocols, training programs, and personal protective equipment (PPE) to reduce risks. While these measures were essential in ensuring basic safety, they were often one-dimensional and didn’t always account for evolving workplace hazards.

As industries grow more complex and workplaces become increasingly automated, the traditional methods are proving inadequate to deal with new, unknown risks. That’s where Industry 4.0 steps in, offering dynamic, proactive solutions that focus on predicting and preventing hazards before they occur.

The Pillars of Industry 4.0 and Worker Safety

At the heart of Industry 4.0 are technologies that promise to revolutionize the safety landscape:

- Internet of Things (IoT): IoT connects machines, sensors, and devices to a network that can monitor and track real-time conditions. In terms of safety, IoT can provide alerts about unsafe conditions such as gas leaks, temperature spikes, or equipment malfunctions.

- Artificial Intelligence (AI) and Machine Learning: AI can analyze data collected from IoT devices to identify patterns and predict potential safety hazards. AI-driven systems can detect anomalies that humans may miss, thus preventing accidents before they happen.

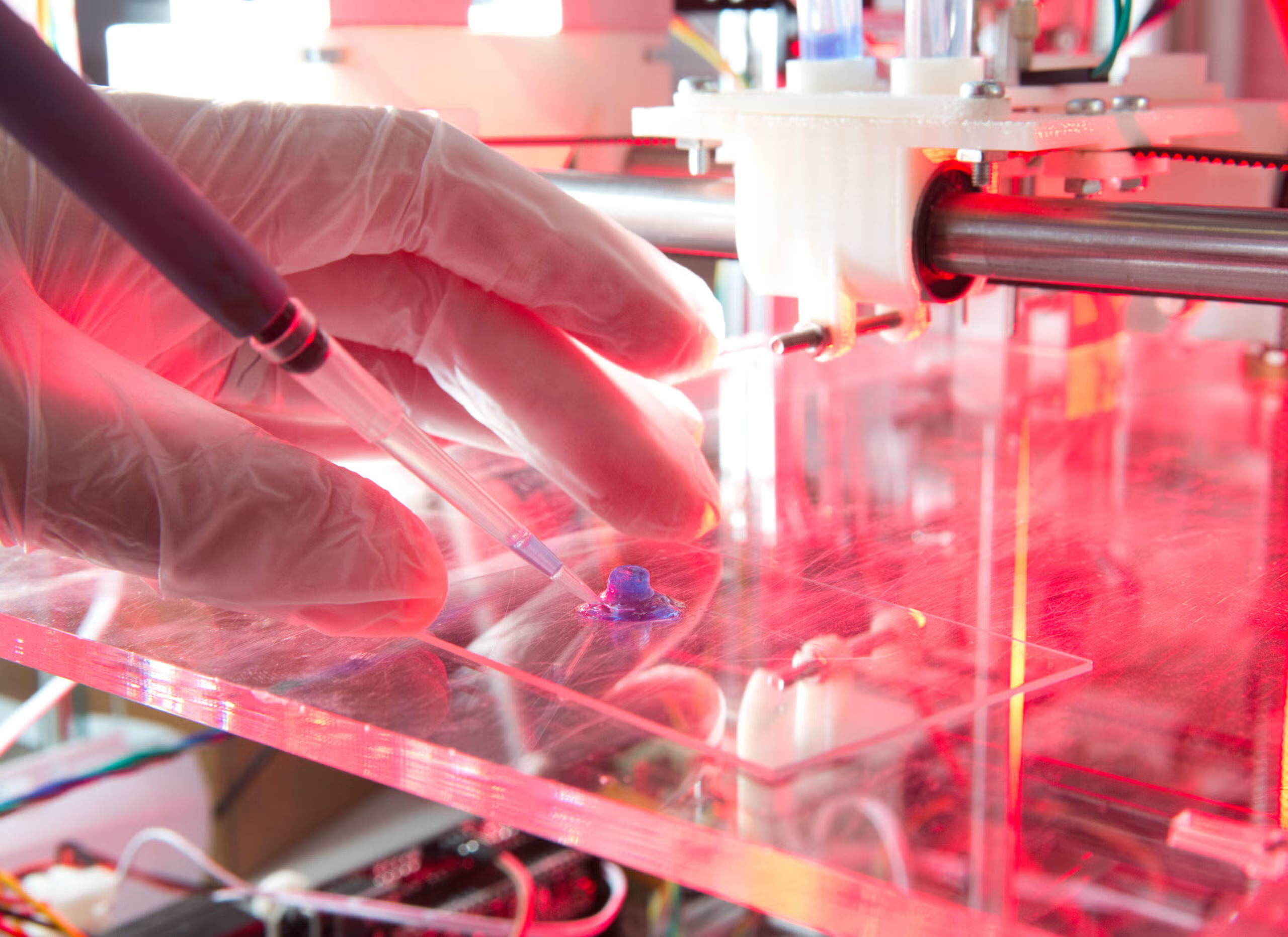

- Robotics and Automation: Robotics are reducing the need for human workers to perform hazardous tasks. From lifting heavy materials to handling toxic substances, robots are taking over dangerous operations, ensuring that workers stay out of harm’s way.

- Big Data Analytics: By gathering and analyzing vast amounts of data, companies can better understand accident patterns and identify areas for improvement. This data-driven approach enables smarter safety decisions and more effective preventive measures.

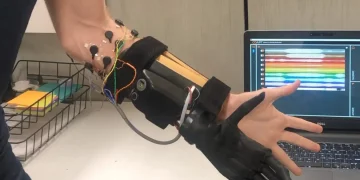

- Wearables and Augmented Reality (AR): Wearable devices, such as smart helmets and exoskeletons, are becoming increasingly common in industrial environments. These devices not only monitor vital signs and detect fatigue but also provide real-time information and guidance through AR interfaces.

The Safety Benefits of Industry 4.0

1. Real-time Hazard Detection and Prevention

One of the most significant benefits of Industry 4.0 technologies is the ability to detect and prevent hazards in real time. IoT sensors can continuously monitor workplace conditions, sending data to centralized systems that analyze environmental factors such as air quality, temperature, humidity, and noise levels.

For instance, in manufacturing plants, sensors embedded in machines can detect early signs of malfunction, such as overheating or pressure buildup, which could lead to equipment failure or worker injury. By receiving real-time alerts about potential hazards, workers can evacuate or take action before an accident occurs.

2. Predictive Maintenance

Traditional maintenance relies on scheduled checks or reactive responses to failures. With predictive maintenance, powered by AI and machine learning, companies can anticipate when equipment is likely to fail, thus reducing the risk of accidents caused by faulty machinery.

For example, a machine might emit certain vibrations or heat patterns just before it breaks down. Predictive analytics can recognize these early warning signs, allowing workers to perform maintenance before the equipment becomes a hazard. By reducing the frequency of equipment failures, Industry 4.0 helps prevent workplace injuries caused by faulty machinery.

3. Robots and Automation: Reducing Human Risk

Robots are increasingly handling dangerous tasks that were once performed by humans. Whether it’s working in hazardous environments, lifting heavy objects, or operating dangerous machinery, robots are designed to withstand conditions that would put human workers at risk.

Take the example of a hazardous chemicals factory where workers used to be at risk of exposure to toxic fumes. With the advent of robotic systems, the factory can now deploy robots to manage chemical processing and hazardous material handling, thereby reducing the potential for accidents involving human workers.

Moreover, autonomous vehicles in warehouses or on construction sites can eliminate the risk of collisions and accidents caused by human error.

4. Wearable Safety Technology

Wearable technology is revolutionizing how we think about personal safety. Wearables can track workers’ physical health in real time, monitoring parameters like heart rate, body temperature, and fatigue levels. When workers are at risk of exhaustion, dehydration, or stress, these devices can issue warnings to the worker or supervisors.

A worker in a high-temperature environment, for instance, could wear a smart helmet with a built-in sensor that tracks body temperature and hydration levels. If the worker’s condition deteriorates, the helmet could alert the worker to take a break or even automatically stop machinery if necessary.

Additionally, exoskeletons are now being used to reduce the strain on workers lifting heavy loads. These wearable devices reduce the risk of musculoskeletal injuries and allow workers to perform physically demanding tasks without overexertion.

5. AI-driven Risk Assessment and Safety Planning

AI is transforming safety management by providing insights that go beyond traditional methods. AI-powered systems can analyze historical data, employee behavior, and environmental conditions to predict potential risks.

For example, AI can be used to model different safety scenarios and determine the most effective safety strategies. If a plant has experienced a series of accidents related to machine malfunctions, AI might recommend changes in equipment or safety procedures based on data trends.

This predictive approach moves safety management from a reactive mode to a proactive, data-driven system. As a result, safety measures can be tailored to specific risks rather than applying a one-size-fits-all solution.

The Challenges of Industry 4.0 in Worker Safety

While Industry 4.0 promises a safer working environment, it also presents new challenges. Adopting these advanced technologies requires careful planning and consideration.

1. Data Security and Privacy Concerns

With the proliferation of connected devices and sensors, massive amounts of data are being generated. This data, while valuable for safety management, can also be vulnerable to cyberattacks. Hackers could potentially gain access to critical safety systems, causing disruptions that compromise worker safety.

For example, if a malicious actor gains control of an IoT sensor that monitors equipment health, they could manipulate the system to overlook hazardous conditions. This risk underscores the importance of securing these systems and ensuring that safety-critical data is protected.

2. Worker Resistance and Skill Gaps

The introduction of advanced technologies often leads to fears of job displacement. Workers may be concerned about automation replacing their roles or the need to learn new, complex systems. This resistance can delay the adoption of safety technologies.

Additionally, there is a growing need for workers to develop new skills to interact with AI, robotics, and IoT devices. Companies must invest in reskilling programs to help workers adapt to these changes and operate new safety technologies effectively.

3. Reliability of AI Systems

While AI is capable of identifying patterns and predicting risks, it is not foolproof. AI systems rely on historical data, which means they can sometimes miss emerging risks or fail to account for new variables. For instance, a malfunction in an AI algorithm could result in a failure to recognize a new type of hazard.

As such, AI-driven safety systems must be regularly updated and calibrated to ensure their accuracy. Workers should also be trained to spot potential risks that AI might miss.

4. High Initial Investment Costs

The implementation of Industry 4.0 technologies can be expensive. Small and medium-sized enterprises (SMEs) may struggle to justify the costs of deploying advanced systems for worker safety, especially when the ROI is not immediately clear.

However, as these technologies become more widespread, prices are likely to decrease, making them more accessible to a broader range of industries. In the long term, the reduction in workplace accidents and injuries could offset the initial investment.

Looking Ahead: The Future of Worker Safety in Industry 4.0

The integration of Industry 4.0 technologies in the workplace is still in its early stages, but the potential for improving worker safety is enormous. As these technologies mature, their ability to prevent accidents, reduce injuries, and promote a safer work environment will only increase.

However, the journey toward fully integrated safety systems is not without its challenges. Data security, worker adaptation, and the high costs of implementation will need to be addressed. But with the right approach, Industry 4.0 could truly revolutionize workplace safety, making it a proactive, data-driven process that protects workers and enhances their overall well-being.